Technical consulting Our expertise for your product quality.

Benefit from decades of experience in the analysis and optimization of rotating and oscillating systems – for maximum product quality, efficient processes, and high operational reliability.

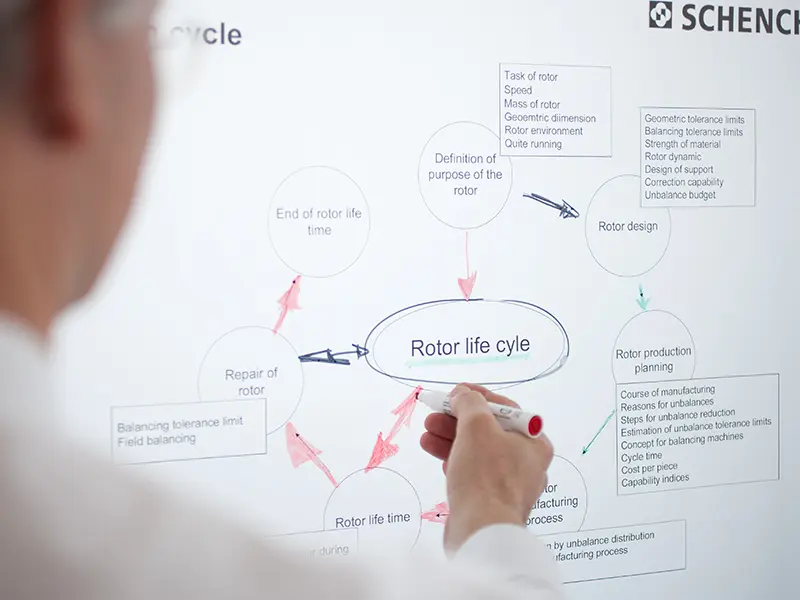

Rotor construction From rotor construction to rotor design.

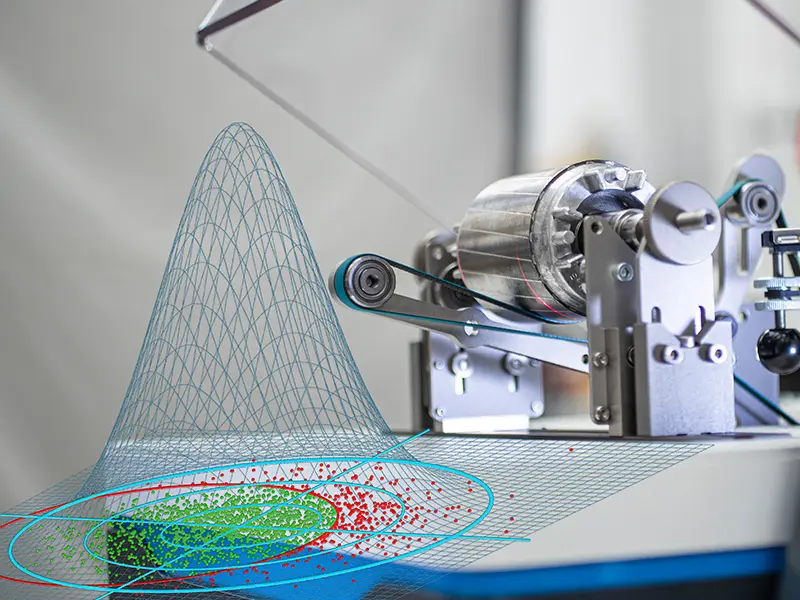

Unbalance budget

Analyze imbalance early on to determine a suitable balancing strategy

Calculation method

Vibration analysis using FEM simulation to support the rotordynamic calculation of your future rotor

Experimental validation

Determination of resonance frequencies, damping, and vibration modes through modal analysis and operational modal analysis

Precision right from the start

Product planning has a significant influence on how vibration-free rotors will run later on. Even at the initial drawing stage, our experts use simulations and calculations to analyze future noise behavior. This allows potential imbalances to be identified early on and successfully minimized during the manufacturing process—for an efficient and sustainable development process.

Our holistic approach to your development process

-

Setting the imbalance budget

-

For an optimal balancing strategy:

During the development phase of a rotor, the future imbalances caused by geometric tolerances of the components are still unknown. An imbalance budget is created to plan the expected imbalance of the rotor that has not yet been manufactured. The goal is to analyze the cause of imbalance at an early stage, adjust manufacturing tolerances, and define a suitable balancing strategy. This allows you to identify critical sources of imbalance early on and take targeted countermeasures before high costs arise from rework. -

Calculation method

-

Calculation of component properties and vibration modes using FEM simulation:

FEM strength analysis is an indispensable tool in modern engineering for virtually testing and validating the mechanical properties of components under real-life loads. FEM calculations can be used to derive design measures that can prevent unwanted vibration, natural modes, or disruptive sound radiation in advance. We analyze and optimize the strength of your products as early as the development phase—for reliable results and efficient processes.

-

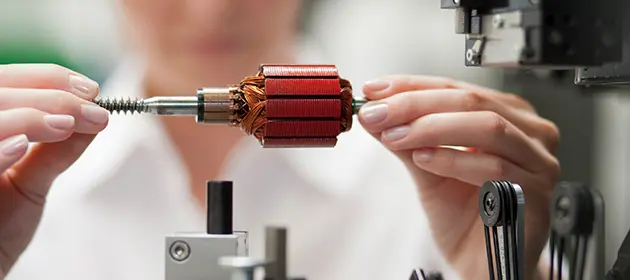

Experimental validation

-

Experimental modal analysis and operational modal analysis for your rotor:

Modal analysis is an important method for evaluating the dynamic behavior of objects and structures, including their natural vibration characteristics and potential responses to internal and external excitations.

By determining natural frequencies and modes in the CAD model, a thorough analysis of complex structures is possible even before the prototype is built. Parameter studies can be used to perform targeted optimizations, taking into account different materials and boundary conditions. The simulation reports provide comprehensive information about the behavior of the structure under different conditions and serve as a basis for further improvements and adjustments. In this way, potential problems can be identified and solved at an early stage, leading to more efficient and cost-effective development.

Operational modal analysis is a very versatile application for determining the vibration patterns of machines and structures under various operating conditions. The vibration patterns are displayed as animated geometric models of the structure, representing a combination of the excitation function and the dynamic properties of the structure.

Prototype testing Your safe path to production

Experimental modal analysis

Determination of resonance frequencies, damping, and the corresponding vibration modes

Spin testing

Safety checks for rotors during and before operation

Vibration analysis

Vibration tests can condense a product life cycle with stress and wear into a short period of time and reveal hidden weaknesses in the design.

Unbalance analysis of prototypes

In our test facility, we analyze the real operating behavior of prototypes—precisely, practically, and reliably. Our vibration testing provides you with the insights you need for further design work. Our centrifugal testing enables strength and expansion tests up to 250,000 min⁻¹. Burst tests allow you to reliably ensure the operational safety of your product. And, if desired, we can support you with suggestions on how to improve your product as a whole.

Our centrifugal testing service for you

Spin test

Pre-Spinning, Overspeed tests, cycle testing, burst testing, etc.

Dynamic expansion measurement

360-degree analysis of individual rotors & analysis of elastic and plastic behavior

Visual inspection

High-resolution visual inspection at standstill or during spinning

Rotor heating

The rotor heater reaches temperatures of up to 250° Celsius, and even higher temperatures on request. Flexible in use, also suitable for burst tests.

Rotor burst tests

Rotor burst tests with high-speed camera

Unbalance analysis

Measurement before/after spinning, detailed analysis of changes, identification of causes in rotor design.

Process optimization Greater efficiency, lower costs, and every detail at a glance.

Process analysis and optimization

As the world's leading manufacturer of balancing solutions, we know how much potential there is for cost reductions in production processes. That's why we analyze and optimize every detail of your processes. For greater efficiency without compromising product quality – tailored to your specific equipment and challenges.

The theory and practice of better balancing In our training courses and workshops, we address your specific challenges and needs. We are happy to offer customized training courses and workshops based on your needs and your project.

Quality assurance Meaningful figures for high quality.

Determining and preparing key figures

Perfection you can prove – Prove the quality of your products and create the optimal basis for continuous process improvements. Our experts support you in determining important, even complex quality indicators and preparing them for your workflow.

Our testing laboratory for balancing technology supports you in complying with and reviewing quality assurance measures, e.g., calibration and adjustment of balancing machines with suitable test weights.

Special balancing service Your specific requirements – our specific services

Balancing service – from standard to special

Our special balancing service includes the balancing of special parts on Schenck machines, whereby we specialize in high-quality and sensitive parts under confidentiality. Particularly in industries such as aerospace, we are a preferred partner due to our special tools for balancing rotors, given the high requirements for cleanliness and precision. In addition, we offer balancing of individual rotors and series, support in the development and production of prototypes, fine balancing, balancing of flexible rotors, high-speed balancing, and speed tests up to 250,000 rpm. Our experienced service team in the balancing centers works closely with customers from various industries to offer customized solutions.

Operational balancing – specifically preventing imbalances during operation

Dirt deposits, damage, and wear lead to new imbalances that can cause damage. Operational balancing effectively reduces vibrations and oscillations. With our SmartBalancer, we balance rotors on site precisely and cost-effectively without dismantling the machine. Our employees compensate for the imbalance by adjusting weights or material in one or two planes.

TurboTest: Analyzing vibrations and imbalances

TurboTest is used both in the laboratory and at the customer's premises for vibration and imbalance analysis. The software enables on-site measurements and supports analysis and problem solving. It measures vibrations and speed to generate analyses such as time signal, spectrogram, FFT, and imbalance calculations.