Centrifugal testing Spin testing for research, development and production.

If rotors are subject to high centrifugal forces during operation, you must be sure that they will not permanently deform or burst. Proven methods include strength tests and durability tests at speeds above the operating speed, burst tests or the performance of service life tests using cycle tests. This gives you the certainty you need for the operation of your rotors. We carry out a variety of necessary tests on your rotating components for new and further developments or as part of quality assurance.

Your advantages with centrifugal force tests from Schenck Our service for you: Prototype testing, spin testing serevice, process optimisation

Early detection of weak points

Quality assurance

Strength test at overspeed

Service life test

Avoidance of expensive rework

Quality monitoring of production

Quality assurance for rotating components

As soon as a component is available as a prototype, its weaknesses are unknown. In our test field, we analyse rotors and assemblies and determine their behaviour in real operation. For rotors that have to withstand high centrifugal forces, we offer our service for strength and expansion tests up to 250,000 min-1, as well as burst tests for operational safety. We also carry out all necessary work on your test specimens for new and further developments or as part of quality assurance.

Our spin service for your prototype

Spin test:

Pre-Spinning, Overspeed tests, cycle tests, burst tests

Performance data:

up to 400kg rotor mass, up to 250,000 rpm, up to 1000mm rotor diameter

Spin test tooling:

Customised design, construction and production

Rotor heating:

up to 250° Celsius. Higher temperatures on request. Also suitable for burst tests.

Dynamic expansion measurement:

360-degree analysis of individual rotors and analysis of elastic and plastic behaviour

Optical expansion and strain measurement:

Full-surface analysis of the entire rotor surface with crack detection - Our own alternative to strain gauges: Rotational Optical Strain System (ROSS).

Rotor burst tests with high-speed camera:

High-speed video during burst tests

Visual inspection & high-definition video:

High-resolution visual inspection at standstill or during the spin cycle

Unbalance analysis:

Measurement of the unbalance condition before and after spinning, including detailed analysis of the changes and assignment of causes in the rotor design

Plastic deformation analysis:

Comparative measurement of the geometry before and after the centrifuging process and detailed analysis of the plastic deformation

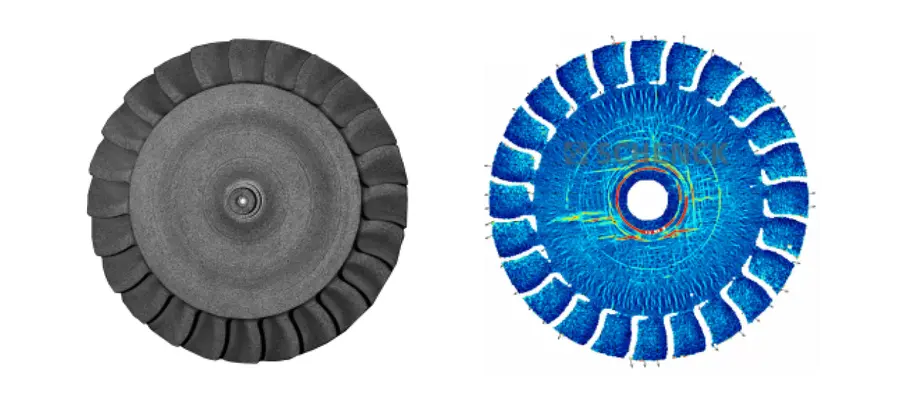

Innovation from Schenck - Optical strain measurement of rotors with ROSS technology

ROSS: Holistic measurement for rotor development

With its ROSS technology (Rotational Optical Strain System), Schenck RoTec enables a completely new form of strain measurement. This measures the deformation of a rotating body in the entire cross-section - during rotation. It is used, among other things, during the development and testing phase of new rotors. ROSS measures the deformation of the entire cross-section of a rotating body during rotation, not just at individual points.

Full surface analysis

ROSS technology detects cracks during testing and collects complete field data. High-resolution cameras and flash lighting capture the rotor multiple times under centrifugal force, enabling weak points to be detected at an early stage. By precisely correlating deformation with rotational speeds, ROSS simplifies design optimization. Unlike conventional methods such as strain gauges, it offers comprehensive, detailed analysis.

Reduce weight, increase performance

ROSS is ideal for the development of rotors that are subject to high centrifugal forces, such as eVTOLs, eDrives and turbine discs. It enables precise analysis of innovative materials such as carbon fibre composites and helps to reduce the amount of material and weight. In the eDrive sector, it also supports the fulfilment of requirements for accuracy, durability and cost efficiency.

Our expertise for your product quality Benefit from decades of experience in the analysis and optimisation of rotating and oscillating systems - for maximum product quality, efficient processes and high operational reliability.

Technological progress for your rotor

We carry out all the necessary work on your test specimens for new and further developments or as part of quality assurance. Simply use our Schenck spin test rigs to gain a better understanding of your rotors. The spin test stands are ideal for development, testing small pre-series and random quality monitoring of production.

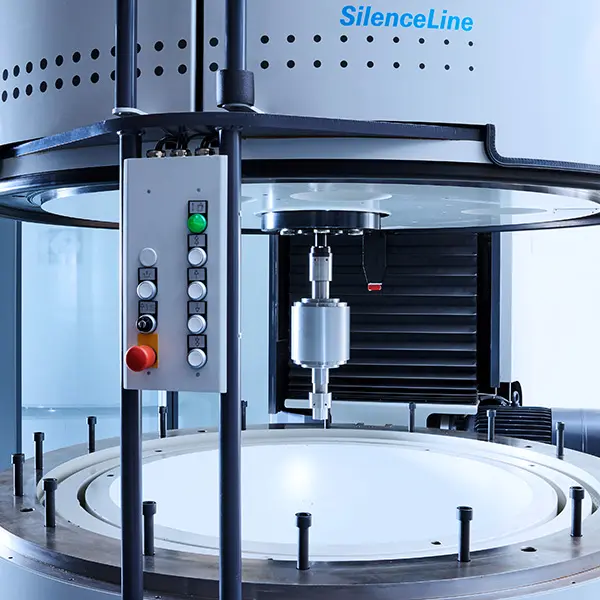

Centrio

Azionamenti elettrici

Electric Drives

Centrio

Spin test systems

Centrio

Schenck Centrio centrifugal test rigs are used to test rotating components in a centrifugal field. These are proven test rigs that are indispensable for the development, manufacture, and quality assurance of rotors in the field of green technology. The main areas of application are: material strengthening, strength testing, burst testing, LCF testing (long-term fatigue testing), and HCF testing.

The test rig contains a vacuum-tight container with integrated burst protection. This is dimensioned by Schenck to absorb the expected fragment energy when a rotor bursts.

- Maximum rotor weight: up to 6,300 kg

- Maximum rotor diameter: up to 2,700 mm

- Maximum rotor length: up to 2,250 mm

- Maximum speed: up to 250,000 rpm

Green Technology Center Support from prototype development to series production

Schenck's Green Technology Centre in Darmstadt accelerates rotor testing with centralised, modern equipment, improves product quality and shortens development times. It offers cycle and burst tests to simulate rotor behaviour over the service life and identify weak points - for targeted optimisation. As a global leader in balancing technology, Schenck RoTec supports manufacturers in rotor development, spin tests, burst analyses, process consulting and certification - especially in the context of e-mobility.

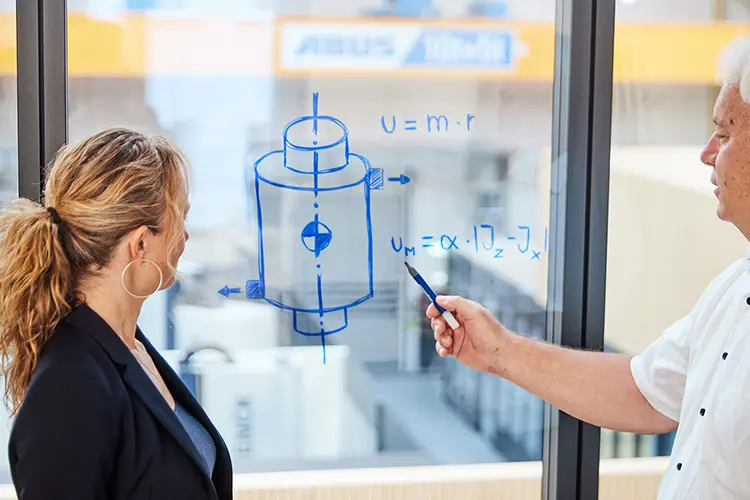

Factory balancing with Schenck

Targeted correction of imbalance during operation

With our SmartBalancer, we can balance rotors of any size and weight quickly, cost-effectively and precisely on site - without dismantling. The portable device detects the imbalance immediately and corrects it directly during operation by adding weights or removing material in one or two planes.