Virio

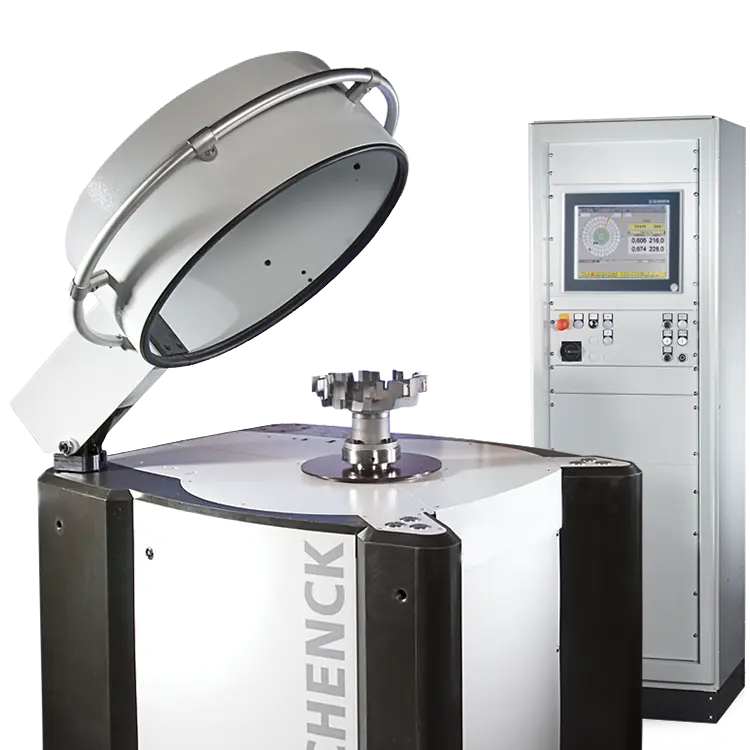

Vertical balancing machines from the Virio series offer you maximum flexibility for all workpieces without their own shaft journal. Whether very small or large rotors up to 300 kg, single or small series production: with Virio, you can balance with precision.

The right spin for your rotors

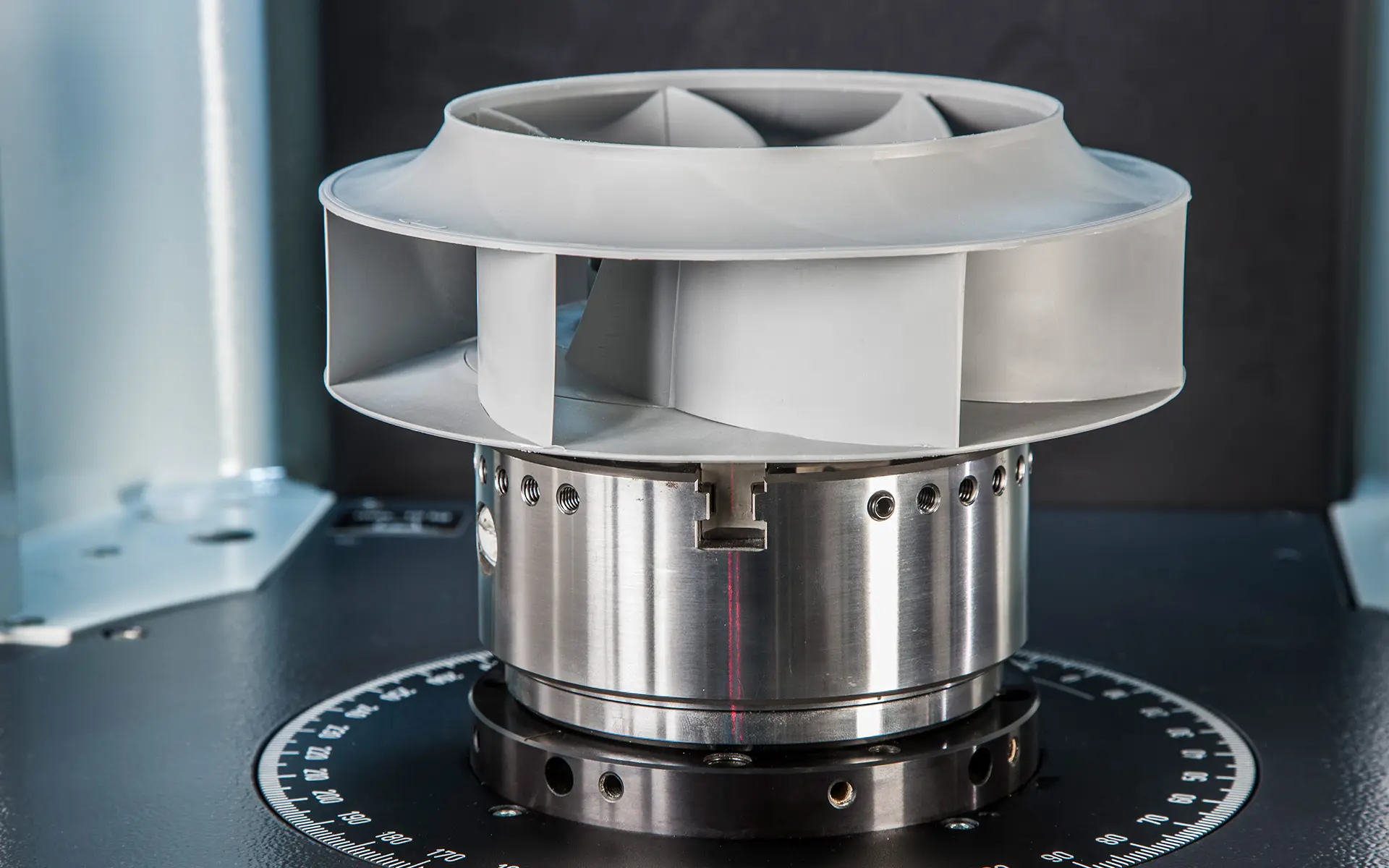

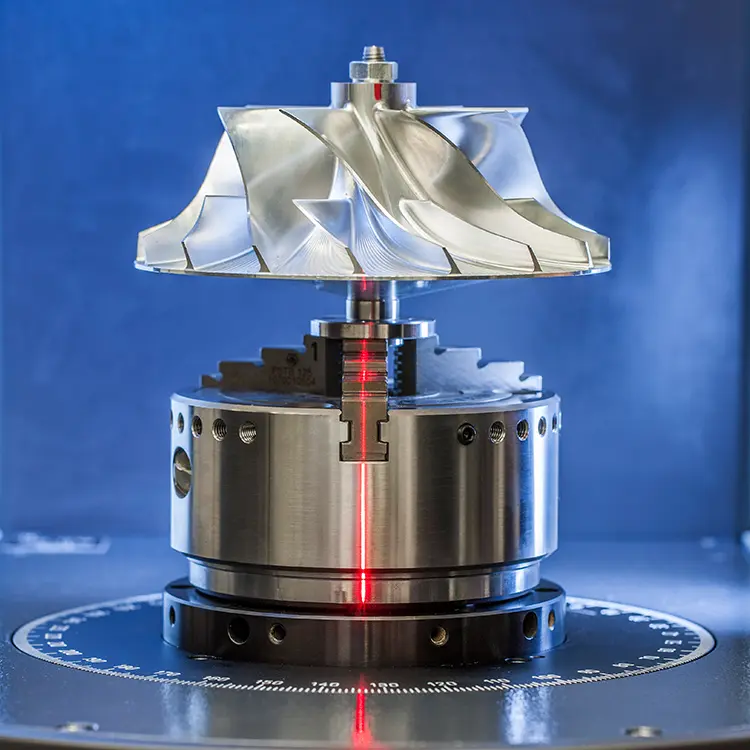

Perfectly balancing disc-shaped rotors Virio vertical balancing machines are ideal for disc-shaped or pot-shaped rotors without their own shaft journal, such as belt or brake discs, pump impellers, fans, clutches, and flywheels. The arrangement of the clamping elements directly on the precision spindle means that no special auxiliary shafts are required, and the rotors can be quickly stored in a workpiece holder. The advantages for you: less time required and more efficient workflows.

Permanently calibrated: Balancing made easy All Virio balancing machines are permanently calibrated. This makes balancing a breeze: simply insert the rotor, enter the geometry data, start the measurement run, and perform the balancing. The unbalance for one or both balancing planes is displayed during the first measurement run – time-consuming calibration runs are a thing of the past. This way, you can achieve perfectly balanced rotors reliably and with just a few balancing steps.

Flexible investment in the future The state-of-the-art and flexible Virio balancing system impresses every day in your workshop and production use with its high practical value. Thanks to numerous well-thought-out details, you can quickly and economically achieve perfect balancing of your rotors. In addition, Virio can be flexibly adapted to a wide variety of balancing tasks – from manual solutions for workshops and repairs to integration into series production.

Advantages of Virio

Universally applicable

For all workpieces without their own shaft journals up to a rotor weight of 300 kg.

Time-saving

With permanent calibration, no additional rotor-specific calibration runs are necessary.

Easy to operate

Logical processes and minimal learning curve, even for complex balancing operations.

High safety standards

CE-compliant protective equipment in accordance with the latest standards.

With top-quality measurement technology

CAB 920 measuring device as a high-end solution for precise data.

Flexibly adaptable

Easy expansion options thanks to the modular system and versatile accessories

Versions of the Virio series Vertical balancing machines for small and large rotors up to 300 kg

Virio

Manually

Vertical

Dynamic

Virio 05

The Virio 05 is the expert for small, lightweight rotors such as vertical fans, pump impellers, compressors, tools, or flywheels weighing up to 500 grams. It is your flexible partner in the workshop and laboratory, in the repair sector, or even in small-batch production. All control buttons are clearly arranged and easily accessible.

- Maximum rotor weight: up to 500g

- Maximum rotor diameter: up to 220 mm

- Maximum rotor height: up to 150 mm

- Plane spacing: up to 20mm

Virio

Manual

Vertical

Dynamic

Virio 5

Virio 5 is the vertical balancing machine for small, lightweight rotors such as small fans without their own drive, centrifuges, deflection wheels, coupling elements, or rotating paint nozzles. The balancing machine can be set up on a table and operated while standing or sitting. The balancing unit, measuring device, and control box are located on a base plate. All control buttons are clearly arranged, ergonomic and easily accessible.

- Maximum rotor weight: up to 5 kg

- Maximum rotor diameter: up to 300 mm

- Maximum rotor height: up to 250 mm

- plane spacing: up to 40 mm

Virio

Manual

Vertical

Dynamic

Virio 15

Just as compact as it is precise: Virio 15 is the ideal choice for balancing disc-shaped or pot-shaped workpieces such as flywheels and pulleys, pump impellers, fans, and transmission components weighing up to 15 kg and with a diameter of up to 400 mm.

- Maximum rotor weight: up to 15 kg

- Maximum rotor diameter: up to 400 mm

- Max. tool length including holder: up to 600 mm

- Spindle speed: 1200 min⁻¹

Virio

Manual

Vertical

Dynamic

Virio 10 - 300

Whether in workshops and repair shops or in series production: Virio 10, Virio 50, Virio 100, and Virio 300 are high-precision balancing machines for a wide range of rotors up to 300 kg. All models can be set up directly on the workshop floor without a foundation, quickly put into operation, and just as quickly relocated.

- Maximum rotor weight: From a maximum of 10 kg for the Virio 10 to a maximum of 300 kg for the Virio 300

- Maximum rotor diameter: up to 810 mm

- Maximum rotor height: up to 450 mm

- FU three-phase drive: 1.5 kW to 4.0 kW

Worth knowing Facts, figures, and data about the Virio series of vertical universal balancing machines

-

Technical highlights

-

Virio 05/5

- Compact tabletop machine for variable installation situations

- Servo drive with digital speed selection and monitoring

- Save Control control system – continuous machine monitoring, permanent monitoring during servicing, very fast fault diagnosis

- Fast and error-free machine setup with the built-in line laser

- Precise turning to the zero position

- Variable drive technology for different weight ranges

- Permanent calibration for easy and fast balancing

Virio 15

- Space-saving monoblock design with integrated measuring station and measuring device

- Easy to operate thanks to permanent calibration – no calibration runs required

- Compensation possible in one or two levels

- Quick and easy commissioning – can be set up without a foundation

- Ergonomic operating concept with good access to all components,

- simple and direct entry of all data via touchscreen,

- Clear and distinct displays and symbols tailored to touchscreen operation

- Easy-to-use swivel protective cover

- Integrated storage container for clamping devices in the machine frame

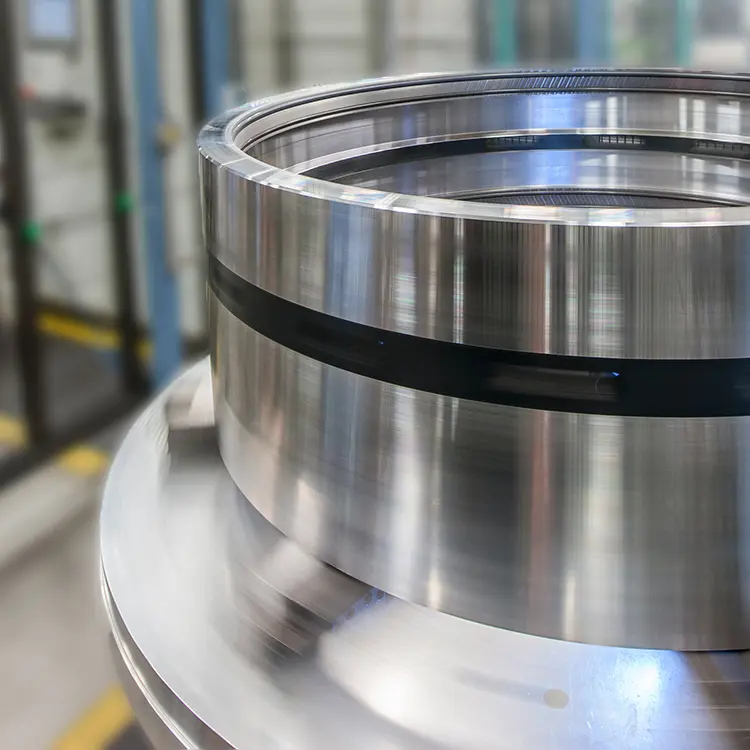

- Machine frame made of mineral casting with excellent vibration damping

- Safe working thanks to compliance with the current machine directives 2006/42/EC

- High measuring accuracy

Virio 10 - 300

- Force-measuring, vertical balancing machine with highly vibration-damping mineral casting housing.

- No foundation required; can be set up and ready for use by bolting directly to the workshop floor.

- No calibration runs, short changeover times thanks to force-measuring principle.

- Precise unbalance compensation directly in the machine – can also be retrofitted.

- High balancing accuracy.

- Weight ranges 10, 50, 100, 300 kg, continuously adjustable three-phase drive for perfect balancing across a wide weight range

-

Areas of application

-

Virio 05

- Suitable for: Vertical fans, pump impellers, compressors, tools, and flywheels

- Area of application: The Virio 05 is typically used in workshops or laboratories, repair shops, or small-batch production facilities

Virio 5

- Suitable for: Small fans, centrifuges, deflection wheels, coupling elements, or rotating paint nozzles

- Area of application: The Virio 5 is typically used in workshops or laboratories, repair shops, or small-batch production.

Virio 15

- Suitable for: flywheels and pulleys, pump impellers, fans, and transmission components

- Area of application: wide range of applications, for example in workshops and in maintenance

Virio 10 - Virio 300

- The Virio 10, Virio 50, Virio 100, and Virio 300 are suitable for a wide variety of balancing tasks in workshops and repair shops or in series production.

-

Special features

-

Schenck universal balancing machines from the Virio series are ideal for single rotors and small series of disc-shaped rotors.

Virio 05/5

The Virio 05 and Virio 5 enable precise balancing of small and medium-sized rotors thanks to a sophisticated machine concept for rotors weighing up to 5 kilograms. The ergonomic design concept contributes significantly to efficient workflows:- optimal accessibility to the work area, the measuring device, and all other important operating elements

- optimized human-machine interface for error-free operation and quick setup

- balancing in one or two planes

- permanent calibration, no time-consuming calibration runs required

- easy setup on different rotors

- low space requirement

Virio 15

Perfect mechanics, precise measurement technology, simple network integration.- Machine frame made of mineral casting: 10 times stronger vibration damping than gray cast iron

- Can also be used as a crane hook machine

- Permanent calibration

- Virio 15 meets all requirements of the applicable machine directives 2006/42/EC and is CE certified. The protective cover complies with the strict provisions of ISO 21940-23 Class C – Protection against flying parts.

Virio 10 - Virio 300

The choice of the best balancing method depends on the rotor type and material. The horizontally and vertically integrated balancing modules of the Virio enable convenient and precise unbalance balancing with all types of balancing directly in the machine. Time-consuming loading and unloading is no longer necessary.- Balancing methods: drilling, milling, punching, riveting, welding

- Modular adaptation to rotor type and material

- Convenient and precise unbalance compensation directly in the machine

- Short changeover times

- Infinitely variable three-phase drive

- Protective device C 600 according to ISO 21940-23

CAB measuring device

The Schenck measuring system for simple, precise, and safe balancing

All data at a glance

Modern measurement technology is at the heart of every Schenck balancing machine. With our CAB measuring devices, you benefit from digital measurement processing for high accuracy, a clear unbalance display, and an ergonomic, easily accessible operating concept.

CAB 920 – innovative all-rounder

Even more possibilities: With the high-end CAB 920 solution, balancing can be achieved with minimal training. This is ensured by the innovative operating concept with guided navigation. Do you have special requirements? CAB 920 can be expanded with additional functions and industry-specific solutions and adapted to your needs.

Precise work made easy

CAB 920 impresses with a well-thought-out operating concept that enables fast and safe working with minimal training. Intuitive handling and high precision in measured value processing result in a high unbalance reduction ratio. Many rotors are already within tolerance after the first measurement run.