Electric Drives

We support you with interdisciplinary expertise in the manufacture of powerful and quiet electric drives.

At every stage of development – from the initial idea and design to series production.

At every stage of development – from the initial idea and design to series production.

Top performance at high speeds

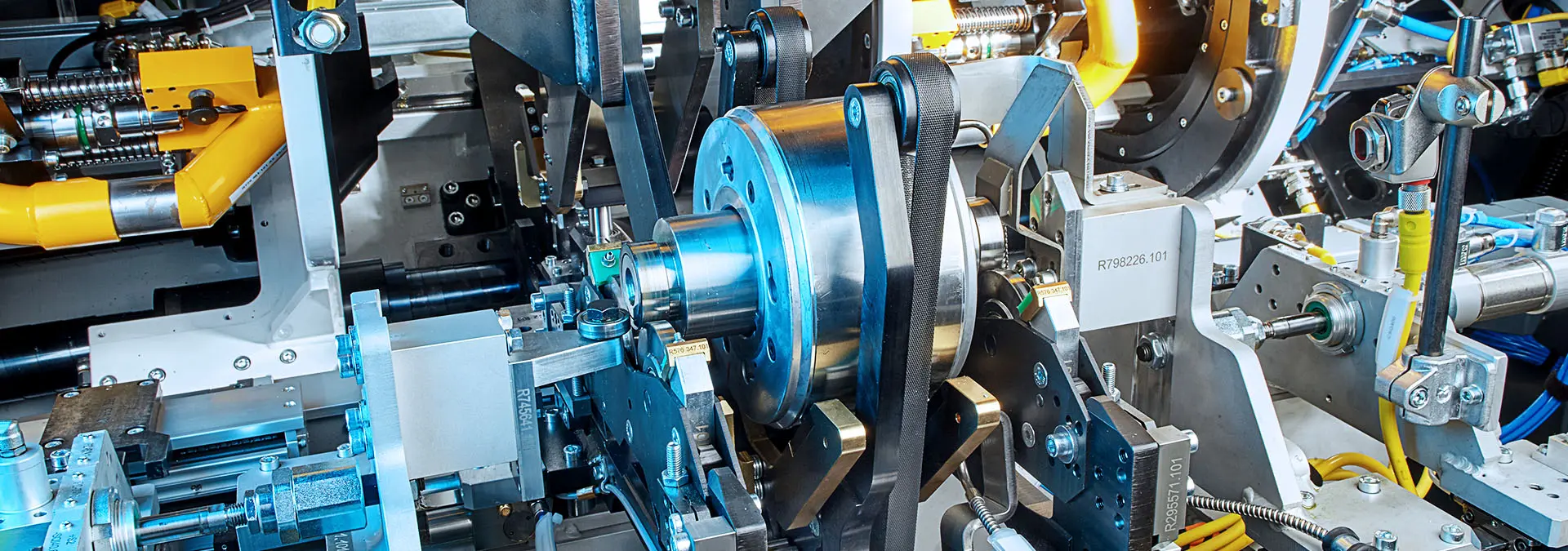

Powerful drives thanks to precise balancing The trend toward higher speeds amplifies the effects of imbalances. Therefore, reliable and high-quality balancing is becoming increasingly important to ensure functionality and quality. With Schenck balancing machines for electric anchors, you can ensure smooth running and a long service life for electric motors. Benefit from maximum performance in a compact design and completely balance (electric) anchors in just one pass.

Flexibility and quality for your manufacturing processes Our balancing machines for electric motors combine versatility and high balancing quality. Thanks to quick changeovers to different rotors, good accessibility, simple controls, and linear units with locking positions, you can make your production processes even more efficient with the eTENO.

Spinning stands: key components in electromobility Spinning stands are indispensable for the development, prototype testing, quality assurance, and production of electric rotors. Due to the low imbalance tolerances of electric rotors, the spinning process and subsequent balancing are crucial. Spinning stands are indispensable in the development, production, and quality assurance of rotors in the field of sustainable mobility. A special quality feature of our spinning stands: The vacuum-tight container with integrated burst protection is dimensioned to absorb the expected fragment energy when a rotor bursts.

Advantages of Schenck balancing machines for electric drives

High flexibility

Versatile balancing concepts and high flexibility in imbalance compensation.

Fully automatic function sequence

Linking of stations and chaining of peripherals as well as precise chaining possible through internal transport.

Easy integration into your production

Low space requirements, efficient use of space, and optimal accessibility.

Short cycle times

Complete balancing of electric anchors and electric rotors in just one pass.

Easy setup and conversion

Good accessibility and simple, intelligent design of the controls for quickly finding positions.

Flexible degree of automation

Loading and unloading of our balancing machines can be integrated into the production process or performed manually.

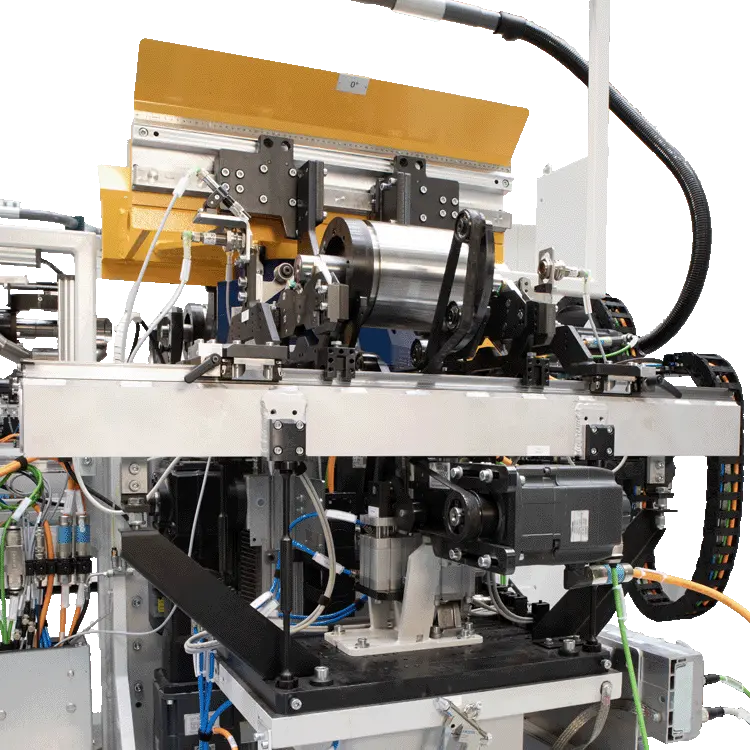

Designs of Schenck balancing systems for eDrives Precise results and short cycle times for efficient series production.

Electric Drives

eDrive

fully automatic

balancing machine

eTENO

The eTENO optimizes the fully automatic balancing of eDrives and rotors of the same design in series production. As a two-station or four-station machine with separate measuring and balancing stations, it enables cycle times of only 50 to 100 seconds and even better results. Storage in the measuring station is usually in rollers, ensuring maximum precision. The orbital positioning of the drilling unit allows balancing over the entire circumference, and the specially designed chip extraction system also works on the rotor shaft. Solutions for radial balancing are available. Optional protective cover.

- Rotor weight: up to 35 kg / 4 stations up to 25 kg

- Wavelength: 150 to 500 mm

- Shaft diameter: 15 to 60 mm

- Package diameter: 60 to 200 mm

- Maximum correction radius: 95 mm

- Package length: 80 to 350 mm

Electric Armature

Electric Drives

Fully automatic

4-station

6-station

KBTU

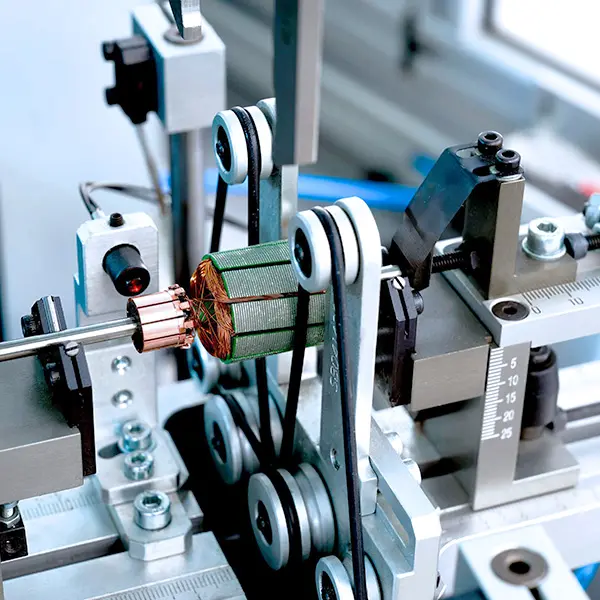

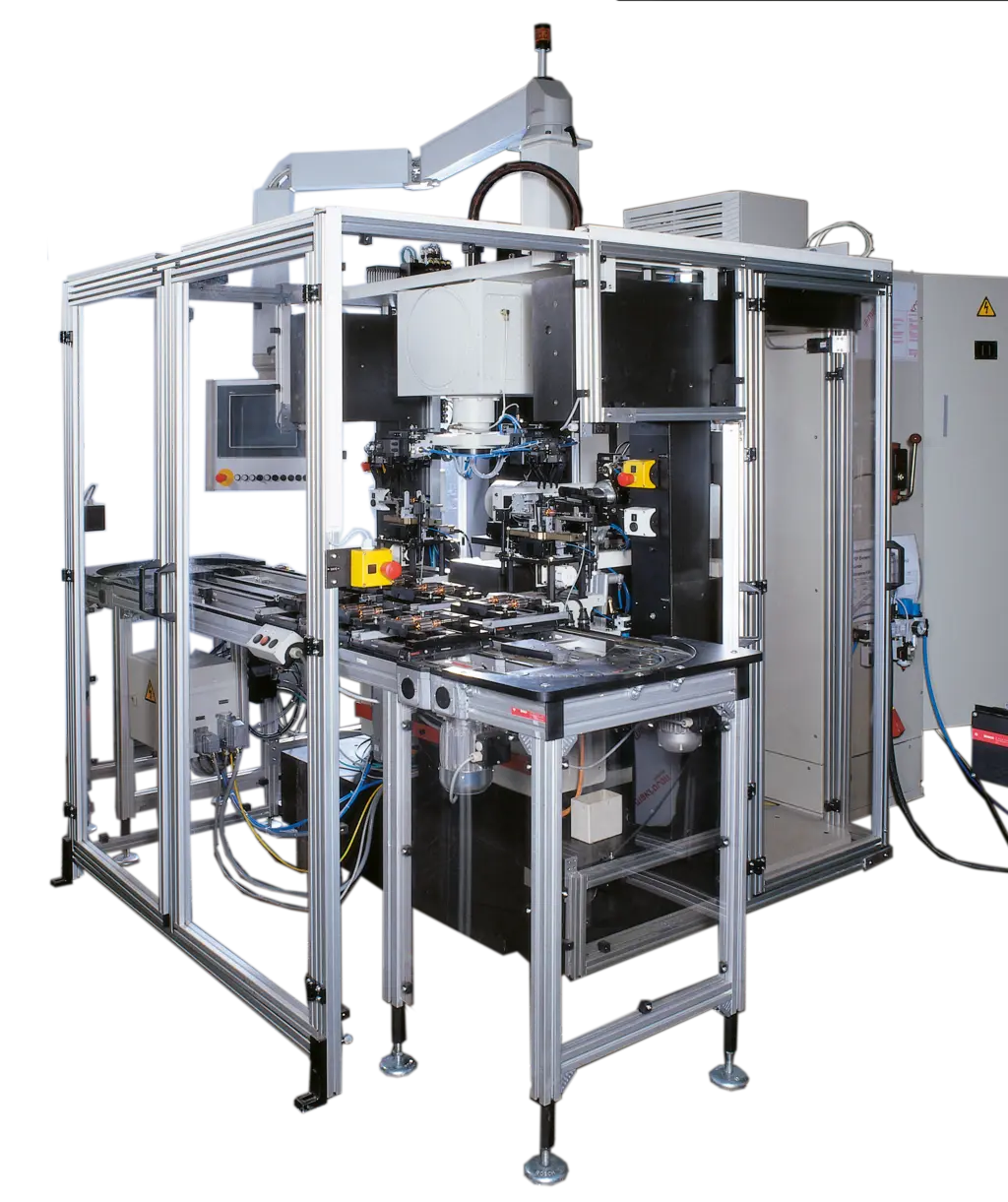

Ideal for use in high-volume production lines, the KBTU series offers 4-station machines or 6-station machines with a fully automatic function sequence for measuring and correcting the unbalance of electric armatures in various designs and sizes.

The unbalance is corrected by milling (profile/polar/slot milling or drilling) in one or two planes. The machine essentially consists of the transfer station to the on-site feeder system, measuring station, common correction station level 1 / level 2, measuring station for audit check, internal pick-and-place lifting and turning transport, as well as the electrical control cabinet and protective device.

Electric Drives

Electric Armature

Fully automatic

5-station

Civo

Ideal for medium to large quantities of up to approx. 2 million electric armatures per year, the CIVO offers you maximum balancing performance in the smallest of spaces.

It is designed for the fully automatic balancing of small electric armatures up to 500 g (optionally up to 3 kg). The machine is a 5-station machine designed for the automatic balancing of electric armatures by milling or optionally drilling. Balancing takes place in one or two planes. The machine essentially consists of the transfer station to the on-site feeder system, measuring station, balancing station level 1, balancing station level 2, measuring station for audit check, internal pick-and-place lift and turn transport, as well as the electrical control cabinet and protective device.

Centrio

Electric Drives

Centrio

Spin test systems

Centrio

Schenck Centrio spin test systems are used to test rotating equipment for the development, manufacture, and quality assurance under centrifugal force. The main areas of application are: material consolidation, strength testing, burst testing, LCF testing (long-term fatigue testing), and HCF testing.

The test rig contains a vacuum-tight chamber with integrated burst protection.

- Maximum rotor weight: up to 6,300 kg

- Maximum rotor diameter: up to 2,700 mm

- Maximum rotor length: up to 2,250 mm

- Maximum speed: up to 250,000 rpm

Interesting facts Figures, data, and facts about Schenck balancing machines for electric motors.

-

Balancing for the perfect rotor in series production

-

The eTENO optimizes the balancing process in series production. The two-station or four-station machines with separate measuring and balancing stations enable cycle times of only 50 to 100 seconds and excellent measuring and balancing results for a wide range of production applications. The orbital positioning of the drilling unit allows balancing over the entire circumference, and the specially designed chip extraction system also works on the rotor shaft. Solutions for radial balancing are available.

Maximum flexibility

- Versatile balancing concepts

- Flexible storage of rotors

- Quick and easy changeovers

- Dual machine concept: as a stand-alone solution with protective enclosure and internal transport, or without protective equipment with particularly flexible installation options for the two stations for easy integration into existing production cells

- Loading and unloading with a robot or a loading portal

High efficiency

- Fully automatic balancing of eDrives and rotors of the same design

- Cycle times of only 50–100 seconds

- Self-turning boring mills for parallel imbalance compensation

- Fast, precise interlinking through internal transport

- Easy loading and unloading

Highest precision

- Fold-away belt drive for perfect measurement results

- (Roller) bearings in the measuring station

- CAB 950 measuring device for maximum precision and easy operation

-

Efficient balancing of (electric) anchors

-

Schenck balancing machines for anchors are available in various sizes and with different degrees of automation. From the six-station balancing machine with fully automatic operation and integrated rotary transfer to the four-station machine and the compact five-station balancing machine with manual loading and unloading options. In every case, you benefit from maximum balancing performance in a small space. With impressively short cycle times for complete balancing. Thanks to their modular design, our systems can be easily combined with automation and feeding devices – from conveyor belts to pallets. Balancing is achieved by polar profile milling, slot milling in components, or polar slot milling in one or two planes.

440 KBTU

4-station machine with fully automatic operation for measuring and balancing the unbalance of wound armatures in various sizes as well as rotors that allow milling balancing. Ideal for use in large-scale production lines.

- Integrated overhead rotary transfer

- Machine base made of mineral casting with good damping properties

- Automatic function sequence, secured by soft PLC

- NC axes for all movements

- Interlinking with production lines

- Powerful measuring device based on industrial PC

- Photo-supported changeover instructions

- Error diagnosis through images and text

- Teleservice for measurement and control technology

460 KBTU

6-station machine with fully automatic operation for measuring and balancing the unbalance of wound armatures in various sizes as well as rotors that allow milling balancing. Ideal for use in large-scale production lines.

- Integrated overhead rotary transfer

- Machine base made of mineral casting with good damping properties

- Automatic function sequence, secured by soft PLC

- NC axes for all movements

- Interlinking with production lines

- Powerful measuring device based on industrial PC

- Photo-supported changeover instructions

- Error diagnosis through images and text

- Teleservice for measurement and control technology

Civo

5-station machine with flexible degree of automation for efficient balancing in electric armature production. Ideal for medium to large quantities of up to approx. 2 million electric armatures per year.

- Flexible degree of automation – loading and unloading either via a pallet conveyor or a manually operated drawer

- Jerk-free acceleration and precise positioning thanks to lift-and-turn transport

- Low noise level and CE-compliant safety device

- High process reliability thanks to fully automatic internal workflow

- Quick commissioning thanks to crane hook design – set up, connect power and compressed air, and the machine is ready for operation.

- Easy to convert and maintain thanks to open machine design

- Unbalance compensation by milling into the sheet metal package – in one or two planes.

- High flexibility through the use of single or multiple milling cutters, oriented to the pole pitch

- Compensation method for oblique and straight grooved armatures

- Interfaces for integration into higher-level production control systems

-

Centrifugal testing – centrifuge testing for research, development, and production.

-

When rotors are subjected to high centrifugal forces during operation, you need to be sure that they will not permanently deform or burst. Proven methods include strength tests and durability tests at speeds above the operating speed, burst tests, or life cycle tests using cycle testing. This gives you the assurance you need for the operation of your rotors. We perform a wide range of necessary tests on your rotating components for new and further developments or as part of quality assurance.

Our centrifugal tests at the Green Technology Center offer you modern analysis options and customized services for your requirements.

With the Centrio centrifugal test rig from Schenck, you get a highly efficient solution for centrifugal testing in your company. With significantly reduced noise emissions, low energy consumption and space requirements, and carefully perfected ergonomics.

Centrio

High flexibility

- Flexible storage of rotors

- Consistent implementation of the balancing process in series production.

High efficiency

- Cycle times of only 40 to 100 seconds

- High balancing quality

- Simple and quick changeover

- Self-turning boring mills for parallel imbalance compensation

- Easy loading and unloading

- Fast, precise interlinking through internal transport

High precision

- Fold-away belt drive for perfect measurement results

- Aerostatic bearings in the measuring station

- Smallest achievable measurement uncertainty (depending on the workpiece): 0.15 µm

CAB measuring systems for series production

Intelligent technology for precision, efficiency, and flexibility.

State-of-the-art measurement technology with simple operation

Much more than basic equipment: The CAB 870 and CAB 950 measuring systems for the series production of electric anchors and electric drives offer you a touchscreen for easy data entry and display of measurement results, a logical operating concept, interfaces for integration into production control systems, as well as automated setup processes, diagnostic programs, and statistics software—everything you need for precise and effective balancing.

Effective balancing

Many standard functions ensure even greater accuracy when balancing electric anchors and electric drives: for example, polar-optimized balancing, measurement of environmental interference, and many more.

Precise mechanics and measurement technology

CAB 950 and CAB 870 are not just measuring devices, but intuitive human-machine interfaces (HMI). They offer convenient and clear access to all machine functions, as well as precise mechanics and modern CAB measurement technology for maximum precision in imbalance compensation.