Smart VibroAnalyzer 95

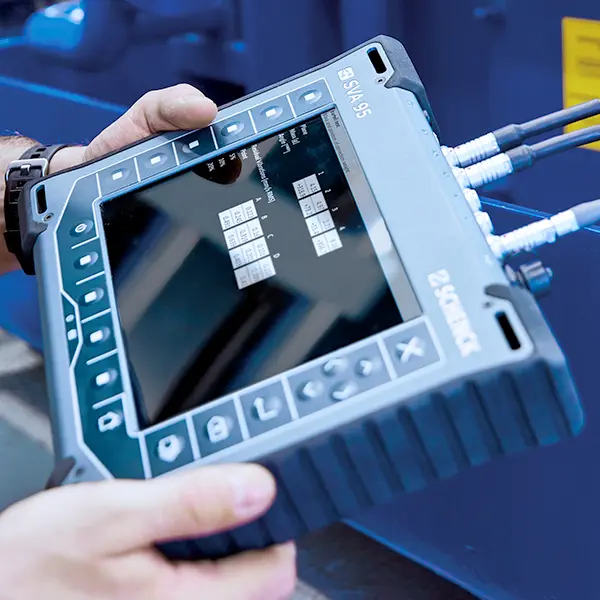

4-channel vibration analyzer with an impressive range of features: The SVA 95 is a powerful, portable device for performing vibration analysis and field balancing

4-channel vibration analyzer with impressive performance range For predictive maintenance, machine evaluation, diagnostics and field balancing

The SVA 95 comes as an analyzer with (1 or 2 plane) balancing and includes all the necessary modules for evaluating machine conditions and has a high expansion level as a multitasking tool with all the functions you could possibly need in practice. It is a universally applicable measuring device that is ideal for quick, easy route-based data collection, monitoring machine condition and operational balancing.

Analyze your data on site with a large color touchscreen that displays clearly visible cursors, bearing fault frequencies, and FFTs, while simultaneously measuring up to four vibration signals with acceleration, velocity, or displacement sensors.

Advantages of the Smart VibroAnalyzer 95 (SVA 95)

Four measurement channels

Four simultaneous measurement channels + speed

Vibration assessment

Vibration assessment according to DIN ISO 10816-3 with diagnostic module

Balancing

Balancing in 1 or 2 planes with advanced balancing supporting up to 8 planes

Sensor types

Compatible with acceleration, velocity, speed, displacement and triaxial sensors

Camera

Internal camera and optional infrared camera

Live analysis

Display of various live measurements on a single screen: FFT, time signal, total vibration, speed, and much more.

Portable vibration analysis at its best

Predictive maintenance, machine evaluation, and fault analysis

Regular vibration analysis is crucial for machine performance and early fault detection. Continuous measurement allows faults to be detected at an early stage, failures to be prevented, life cycle costs to be reduced, and productivity to be increased.

The SVA 95 offers powerful diagnostic capabilities that enable multi-channel analysis, thermal imaging, ultrasound, octave measurement, raw data recording, condition monitoring, and balancing for efficient maintenance and maximum productivity.

Versatile and cross-industry The Smart VibroAnalyzer 95 offers versatile analysis and can be used in a wide range of applications including power, process, and petrochemical industries. It is compatible with acceleration, velocity, displacement, and triaxial sensors, and an ultrasound microphone. Its diverse measurement and diagnostic functions are ideal for maintaining a wide variety of machines, including research and development, product test cells to machines, and systems in continuous operation.

Sustainable quality assurance for your business

The Smart VibroAnalyzer 95 offers comprehensive solutions for sustainable quality assurance in your company. All results are stored directly in the device and can be accessed at any time. Easy transfer to a PC enables professional presentation, analysis, and archiving in the Schenck Diagnostic Center software. This software allows the use of symptom indicators and detailed investigation of bearing faults using an extensive database.

In addition, the Schenck Diagnostic Center can be expanded to generate reports and manage custom reports.

Software modules that move you forward The Smart VibroAnalyzer 95 is one of the most powerful mobile vibration analyzers currently used for machine analysis. Thanks to its extensive range of features, the SVA95 can be used to perform almost any task.

SVA 95 Kit

The Smart VibroAnalyzer 95 is the most powerful vibration measuring device on the market, with numerous software modules included in the scope of delivery.

Optional accessories

SVA95 has a wide range of different sensors (acceleration, speed, distance, triaxial). Existing sensors can continue to be used with new connection cables.

Navigation and operation

The SVA95 features a 9.1" color touch display for professional vibration analysis and side control buttons for safe operation in various environments.

Included Modules

-

Diagnostic

-

This module is an expert system for the automatic detection of possible machine errors.

It displays the following errors:

- Overall condition of the machine

- Overall condition of the bearings

- Severity of the unbalance fault

- Severity of mechanical looseness

- Severity of misalignment

- Displays via text if the found condition is good or severity of fault or provides a velocity spectrum displayed on the bottom of the screen.

-

Analyzer

-

With the Analyzer Module, the user can select the type of measurement (from simple overall values to FFT’s and time signals, to more advanced measurements such as orbits using displacement / proximity probes) and set up multiple, synchronized, simultaneous measurements from all channels with settings such as frequency range, sampling rates and units.

- Real-time FFT

- Demod/envelope analysis

- ACMT – low speed bearing analysis

- Orbit Measurement

- User Band Pass Analysis

- FFT Resolution: Min: 100 lines, Max: 3,276,800 Lines

- Fully simultaneous for 4 channels

- Crest Readings

- Time signal measurements

- Phase Shift

- DC Measurements

- Centerline Measurements

- Smax

- Overall Measurements

-

Balancer

-

This module allows for balancing equipment in situ, both in the field and during final assembly, providing a quality product.

- Multiple balancing types such as Polar (0-360 degrees), component and fixed weights

- Flexible Visualization of balancing: polar plot and table overview

- Optimizing the final vibration level at the two bearings supports in an early stage while balancing in a single plane

- Allows for Rotor setting to calculate balance quality according to ISO 1940

-

Advanced Balancer

-

With the advanced balancing module, balancing of flexible and rigid rotors in up to eight (8) planes is possible. Multi-plane is used for rotors with complex geometries that exhibit significant unbalance in multiple planes. In addition, the Advanced Balancer Module can assist with complicated jobs where the number of measurement points is larger than the number of correction planes available.

-

Ultrasound-Recorder

-

This module uses a microphone (sold separately) to allow the measurement of sound that is inaudible to the human ear.

- Typical applications that benefit from the use of ultrasonic measurements are the detection of air leaks, electrical arcs or the early detection of bearing faults.

-

Bump Test

-

The bump test determines the natural frequencies of a machine system. In the context of a rotating machine, this pertains to those ranges of rotational speeds within which vibrations are disproportionately amplified due to resonances, posing the potential to damage the machine (Smart VibroAnalyzer 95 only).

-

Lubrication Greasing Control

-

This module can be used to monitor and control bearing lubrication processes. Both a lack or excess of lubricant is harmful to a rolling element bearing. This module measures the actual bearing lubrication status and informs the operator when the lubrication state is optimal, relative to programmed lubrication guidelines. (Smart VibroAnalyzer 95 only).

-

Stethoscope

-

This module is designed for listening to vibrations on the Smart VibroAnalyzer 95.

- Uses standard headphones

- Can be recorded and played back

-

Octave Analysis

-

With the Octave Analysis Module, you can measure audible sounds by connecting a microphone to the Smart VibroAnalyzer 95.

- Measure sound levels and octave spectrums with selectable resolutions of 1/1, 1/3, 1/12, or 1/24.

-

Camera

-

The module is equipped with an optical camera that allows the SVA 95 user to capture images of the machine they are working on.

-

Tracking

-

With the Tracking Module, resonances in the system can be determined by the measurement and graphical display of the amplitude and phase angle of the rotational vibrations as a function of the speed. The Tracking Module uses the raw vibration signal and visualizes the amplitude and phase angle in a bode, Nyquist, FFT waterfall diagram, and numerical reading. This ensures dedicated balancing outside the range of machine resonances.

-

Data Collection

-

One of the fundamental principles of condition monitoring is data collection based on predefined alarm limits. The Data Collection module is used for the periodic collection of vibration data of the balance of plant machinery. Simply create a route tree with measurement points and locations in the Schenck Diagnostic Center Software and upload the route in the Smart VibroAnalyzer 95. With the uploaded route you are prompted by the unit to move from machine to machine with specific measurement points to efficiently collect data.

The Smart VibroAnalyzer will notify you of an alarm situation that can easily be reviewed on the unit to provide onsite feedback. After the route is completed, the collected data can be transferred back to the Schenck Diagnostic Center Software via USB-C cable to store readings, review trends, analyze data and provide reports.

Technical data

Input Channels

- 4 x AC/DC, 1 x TACHO for speed probe/external trigger

Frequency ranges [-3 dB]

- Maximum range: 0.35 Hz – 90 kHz (1 CH, 194 kHz sampling)

- Maximum range: 0.35 Hz – 5 kHz (4 CH, 64 kHz sampling)

- Minimum range: 0.35 Hz – 25 Hz (4 Ch, 64 Hz sampling)

Sampling mode

- Fully simultaneous for 4 channels

FFT resolution

- 100 to 3.276.800 lines

Display

- Color: 1125 x 800 pixels

Processor

- Intel Atom 1.9 GHz

Memory, Route

- 64 GB, max., 16 GB for one route, number of routes is limited by free memory only

Raw signal recorder

- 64 kHz sampling frequency

- 4 Ch memory consumption 3 GB/hour

- 4 Ch total recording – 20 hours

Interface

- USB 3.0, 2.0 compatible

Operating temperature range

- -10 °C to +50 °C (-14 ºF to +122 ºF)

Power

- Battery 8 hours of operation

Case

- IP 65 rating, aluminium heavy duty

Size & Weight

- 29.5 x 23 x 4.9 cm, 1.98 kg

Languages

- German, English, French, Spanish, Italian, Russian, Hungarian, Romanian, Polish, Czech, Thai, Chinese

Built-in camera

- 5 MP, autofocus

Scope of delivery Everything you need with comprehensive accessories for immediate use

1 Smart VibroAnalyzer 95 measuring unit

- with integral rechargeable battery and user dialogue in German, English, French, Spanish, Italian, Russian, Hungarian, Romanian, Polish, Czech, Thai, Chinese

- 1 acceleration sensor kit with:1x AS-053 Single Axis Acceleration Sensor, 1x magnet for flat and curved surfaces, 1x connection cable, 5 m long

- USB-C connection cable to the PC, 1.5 m long

- 1 combined power supply unit/charger with adapters

- 1 screen protector

- 1 hard shell case for measuring unit and accessories

Modules included

- Diagnosis

- Analyzer

- Balancer

- Advanced Balancer

- Ultrasound recorder

- Bump test

- Lubricant inspection

- Stethoscope

- Octave analysis

- Camera

- Thermal Imaging (IR Camera additional)

- Tracking (available option)

- Data collection (available option)

Optional accessories:

- Acceleration sensor kits

- Triaxial acceleration sensor

- Microphone

- Laser reference kit