Pasio

Pasio are universal balancing machines for horizontally mounted rotors from a few grams up to 700 kg. Thanks to Schenck ONE software, you have access to valuable data and applications for the entire balancing process at all times.

Cutting-edge technology for perfect balancing

Exact balance measurement for maximum precision The Pasio series stands for high-precision unbalance detection and accurate balancing. This is ensured by the perfect interaction of individual machine components such as machine beds, drive components, and control components. The sophisticated mechanics and accurate measurement technology enable residual unbalances of 0.1 gmm to 1.5 gmm per plane for maximum precision.

Compact and intuitive Set up, align, connect, and balance—that is the design philosophy behind the Pasio series. These universal balancing machines are ergonomically designed, quick to set up, and easy to integrate into your networks. Particularly relevant is the Pasio balancing machines have a small footprint. This allows you to position them flexibly in your factory.

High process reliability, more transparency Process reliability and innovation are standard for us. Pasio balancing machines are equipped with Schenck ONE measurement software for transparent and reliable balancing. The intuitive user interface (HMI) of every Pasio also ensures error-free operation, tool-free changeovers, and efficient production processes.

Advantages of the Pasio

Universally applicable

Ideal for a wide range of applications with rotor weights from a few grams up to 700 kg.

Flexibly customizable

Modular structure, sophisticated design and versatile accessories for high flexibility during set-up and balancing.

User-friendly

Intuitive commissioning, permanent calibration, ergonomic design, and easy access to components.

Short changeover times

Easy machine setup for different rotor types thanks to precise adjustment elements and scales for accurate positioning.

Precise measurement results

Automatic start-up of the rotor-specific speed via precise speed control.

State-of-the-art measuring software

Connection to Schenck ONE: innovative software and modern HMI for transparent, safe balancing.

Versions of the Pasio series Fast and safe for perfect results in every rotor weight class

Pasio

Manual

Horizontal

Pasio 005/05/5

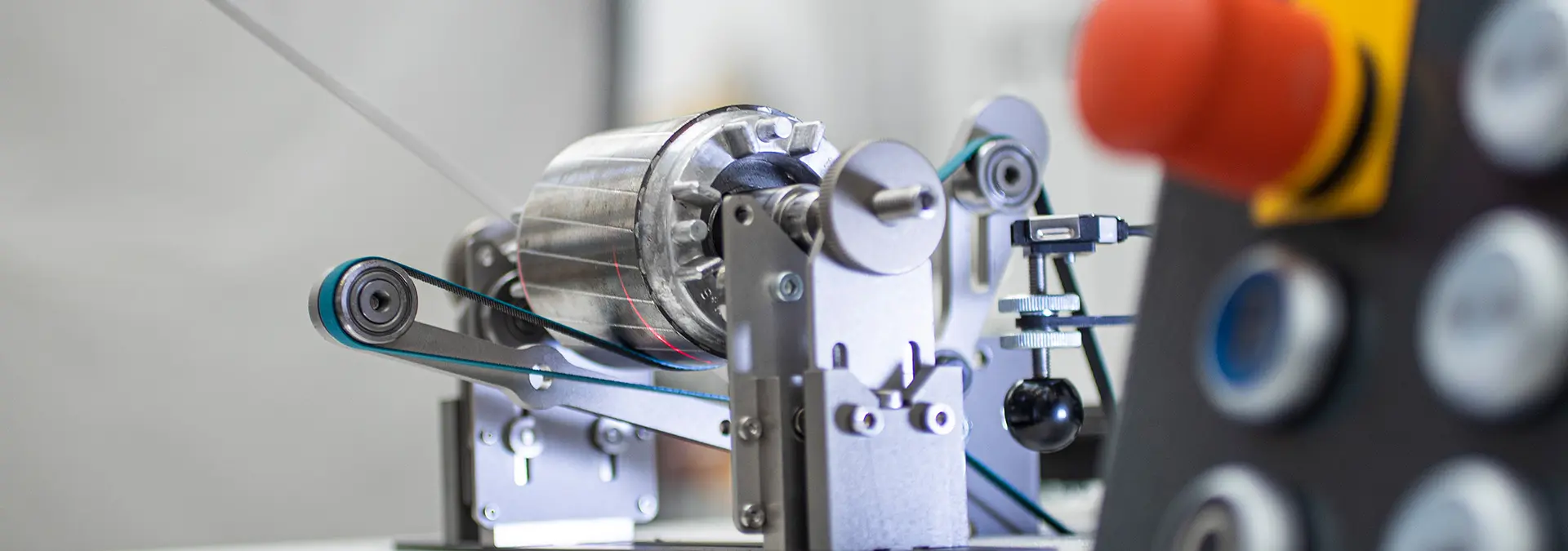

Ideal for small and miniature rotors from dental tools and miniature fans to complete assemblies in research, development, and small-batch production, as well as repair and maintenance work. The compact Pasio 005, Pasio 05, and Pasio 5 balancing machines are tabletop machines that deliver big results in the smallest of spaces. They are technically optimized for their respective areas of application, with different drive concepts and rotor bearings.

- Maximum rotor weight: up to 5 kg

- Maximum rotor diameter: 30 to 150 mm

- Bearing center distance: Flexibly adjustable from 45 to 240 mm

- Bearing journal diameter: For bearing journals from 1 to 22 mm (optionally up to 40 mm)

Pasio

Manual

Horizontal

Pasio 15

The Pasio 15 universal balancing machine is the right choice for a wide range of rotors weighing up to 15 kg, and examples are, electric anchors, fans, and aggregates. The Pasio 15 is ideal for small series production and development, as well as in the repair and maintenance sector. Commissioning is easy: set up, align, connect, balance. The convenient one-hand folding bracket drive makes it easy to store the rotor in the machine.

- Maximum rotor weight: up to 15 kg

- Maximum rotor diameter: up to 350 mm

- Bearing center distance: Flexibly adjustable from 60 to 600 mm

- Bearing journal diameter: for bearing journals from 6 to 30 mm

Pasio

Manual

Horizontal

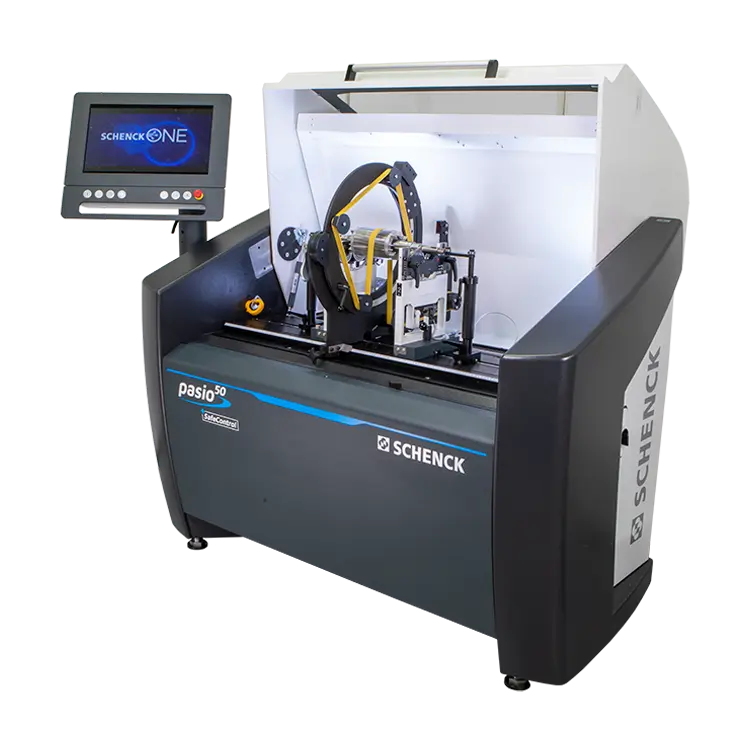

Pasio 50

Pasio 50 is designed for rotors weighing up to 50 kg with a maximum rotor diameter of 600 mm and a length of 1,000 mm. The balancing machine covers a wide range of rotors, especially in manufacturing and repair operations. The sophisticated mechanics and perfect measurement technology enable residual unbalance of less than 0.1 gmm/kg per plane.

- Maximum rotor weight: up to 50 kg

- Maximum rotor diameter: up to 600 mm

- Bearing center distance: Flexibly adjustable from 50 to 1,000 mm

- Bearing journal diameter: for bearing journals from 9 to 63 mm

Pasio

Manual

Horizontal

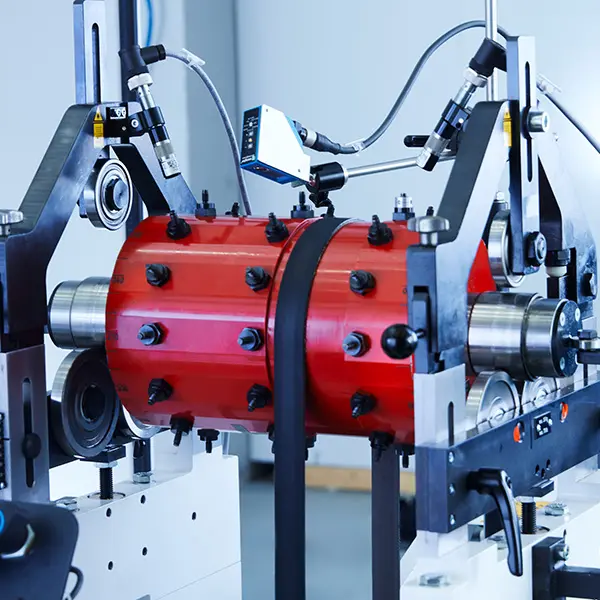

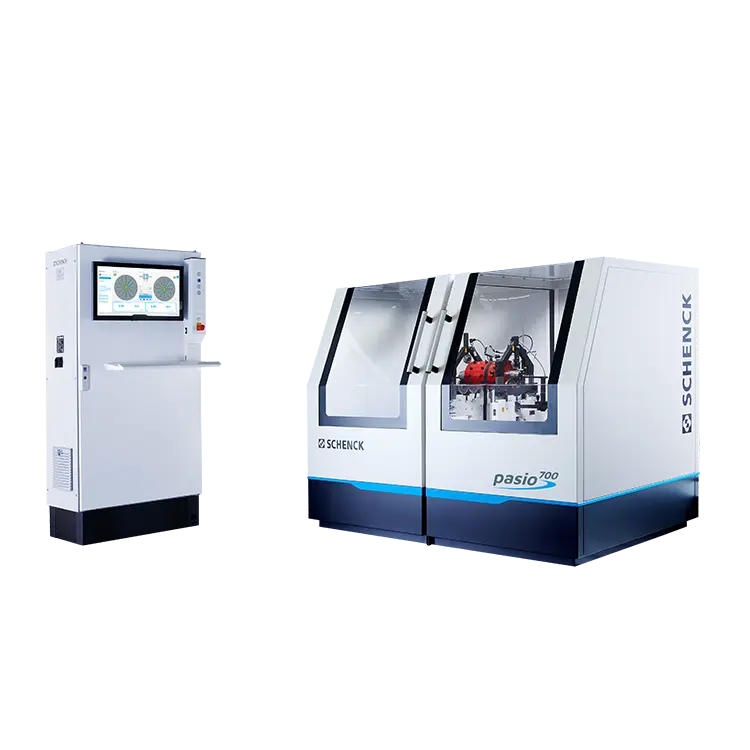

Pasio 100/300/700

New to the Pasio series, with Pasio 100, Pasio 300, and Pasio 700, you get state-of-the-art balancing machines for horizontally mounted rotors weighing up to 700 kg, such as, fans, spindles, electric anchors, compressors, rollers, turbochargers, and much more. Maximum ease of use is ensured by features such as a compact pneumatic control unit for belt tensioning and a large, clearly arranged touch screen (24") with flexible height adjustment.

- Maximum rotor weight: up to 700 kg

- Maximum rotor diameter: up to 1,260 mm (depending on protective device)

- Bearing center distance: Belt drive 1,280 to 2,280 mm, drive shaft 690 to 1,690 mm

- Bearing journal diameter: For bearing journals from 9 to 80 mm (optionally up to 160 mm)

Introducing the new Pasio 700

Worth knowing Facts and figures about the universal balancing machines in the Pasio series

-

Technical details

-

Pasio enables efficient production processes and quick changeovers thanks to its clear layout, good accessibility, simple and intelligent design of the controls, and scales for precise positioning and accurate retrieval of setup positions.

- Reliable balancing, and also of magnetized rotors on request

- Servo drive with digital speed selection and monitoring for rotors up to 50 kg

- Convenient one-hand folding handle drive for easy storage of the rotor in the machine for rotors up to 50 kg

- Sophisticated mechanics and perfect measurement technology for residual unbalances from 0.01 gmm (rotor weight up to 50 g) to 1.5 gmm (rotor weight up to 700 kg) per plane

- Optimized API management and easy integration into customer networks

- Self-diagnosis for fast fault detection and elimination

- Wide range of options for special requirements

- Automatic start-up to the individual rotor-specific speed via precise speed control

- Easy-to-adjust and easy-to-use line laser for precise angular positioning

- Variable drive technology for different weight ranges

-

Area of application

-

Pasio 005/05/5

- The Pasio 5 series is ideal for very small workpieces such as micro motors, dental turbines, miniature fans, and complete assemblies.

- It is used in research and development, small-batch production, and repair and maintenance.

Pasio 15

- The Pasio 15 is ideal for small workpieces such as electric armature, fans, and complete assemblies.

- It is used in small-batch production, development, and repair and maintenance.

Pasio 50

- The Pasio 50 enables precise balancing of a wide range of rotors. Cylindrical rotors with their own shaft journals and disc-shaped rotors with auxiliary shafts can be balanced easily and precisely.

- It achieves maximum accuracy when changing over to different rotor types: precise positioning of the bearing stands, belt drive, and reference sensor thanks to its smooth alignment.

Pasio 100/300/700

- Pasio 100, Pasio 300, and Pasio 700 enable precise balancing of a wide range of rotors.

- They are ideally suited for a variety of rotors, such as fans, spindles, electric armature, compressors, rollers, or turbochargers.

- Permanent calibration, ergonomic design, and logical processes make them easy to operate.

- The modular system and versatile accessories make them extremely flexible.

-

Special features

-

Pasio 005/05/5

- Pasio 05 and Pasio 5 are displacement-measuring or force-measuring horizontal balancing machines with permanent calibration for standing or seated operation.

- The Pasio 005 uses the displacement-measuring method due to its higher accuracy.

- The complete workstation consists of the following main components: machine table, balancing mechanism with roller or prism bearings, belt drive, measuring device, and control system.

- The machine can be set up and is ready for use without a foundation or screw fastening.

- Manual unbalance compensation is achieved by adding material directly to the machine or by removing material.

- Conversion to other rotor types can be carried out in a very short time thanks to its simple handling.

- Compensation in two planes or separately according to static unbalance/moment unbalance is possible.

- Angle adjustment display for belt drive.

Pasio 15

- Pasio 15 is a force-measuring, horizontal balancing machine with permanent calibration.

- The complete workstation consists of the following main components: mineral casting housing with integrated control system, balancing mechanism with roller or prism bearings, belt drive, and protective cover.

- The machine can be set up and is ready for use without a foundation or screw fastening.

- Manual unbalance compensation is carried out by adding material directly to the machine or by removing material on optional manually operated or semi-automated processing units.

- Conversion to other rotor types can be carried out in a very short time thanks to simple handling.

- Balancing possible in two planes or separately according to static unbalance/moment unbalance

- Angle adjustment display for belt drive

Pasio 50

- Pasio 50 is a force-measuring, horizontal balancing machine with a patented wrap-around belt drive for fast, ergonomic storage and drive of rotors.

- Compact design with mineral cast housing for optimal vibration damping.

- Class C protective cover according to ISO7475.

- Balancing possible in two planes or separately according to static unbalance/moment unbalance.

- Angle adjustment display for belt drive.

Pasio 100/300/700

- Pasio 100/300/700 are easy to use, as no calibration runs are necessary thanks to the force-measuring principle.

- Compensation possible in two planes or separately for static unbalance/moment unbalance.

- Storage of rotors on original or auxiliary shafts or with mounted roller bearings (optional).

- Angle adjustment display for belt drive and final drive

- Pasio 100/300/700 offers a selectable automatic measuring cycle with continuously adjustable values for start-up, measuring, and braking times

Schenck ONE

Schenck's software ecosystem for easy, precise, and safe balancing

Gain a competitive edge with Schenck ONE

Schenck ONE is the leading software platform for balancing - our digital solutions support customers at the balancing machine and beyond in all related work steps. This holistic approach offers you the right solution for every challenge throughout the entire balancing process.

Digitalization as a driver of productivity

Schenck ONE combines precise measurement software with supporting software solutions, whose ever-expanding range of functions you can access using your browser. This allows you to keep track of all your data and processes and operate with maximum efficiency.

Digital Solution. Real Value.

The user-centric Schenck ONE software offers you tangible added value: it enables error-free work steps thanks to intuitive user guidance and location-independent machine settings with secure user management. We provide you with software updates automatically and you decide when to run them.