HM

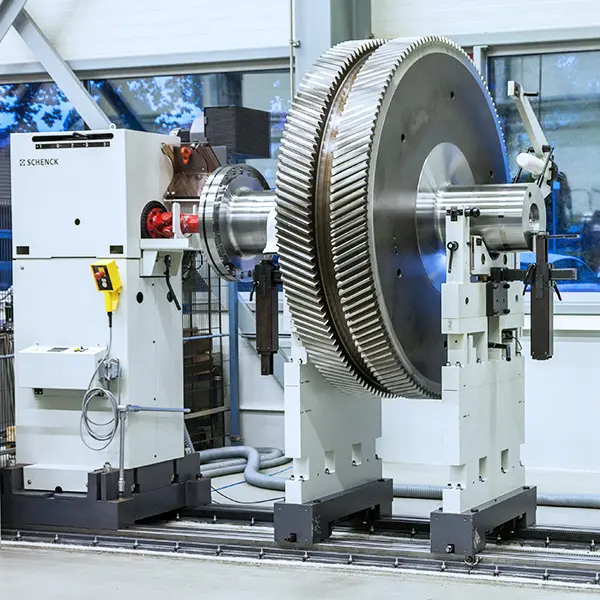

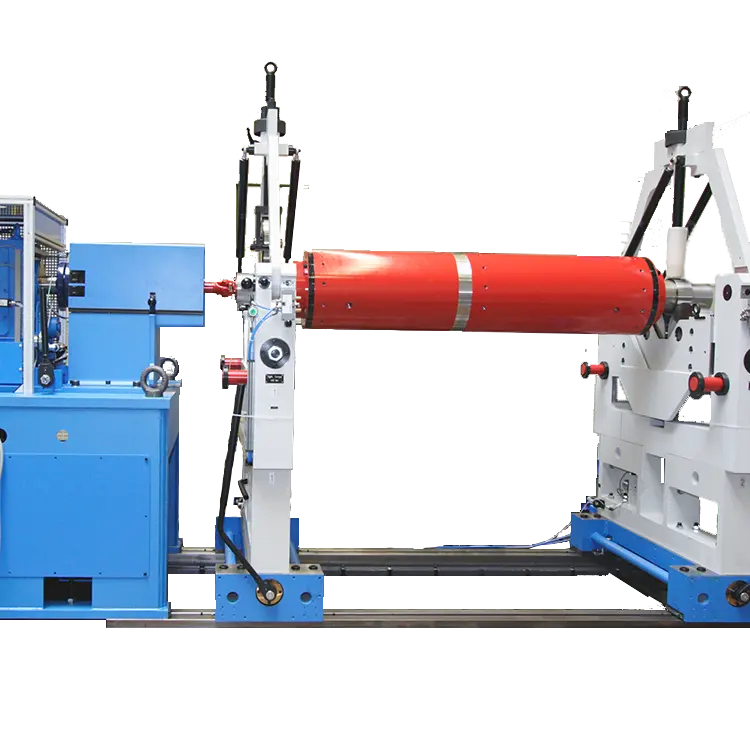

The HM series universal balancing machines from Schenck are ideal for balancing horizontally mounted rotors with maximum precision and flexibility for many areas of individual applications. Their modular design enables these machines to meet most balancing requirements in single-unit or in high volume production making them suitable for smaller businesses and workshops and for manufacturers of larger quantities.

The all-rounders among balancing machines.

Modular system for maximum flexibility Adapt your balancing machine to your needs. Whether for single rotors or small series, the modular system and versatile accessories make the HM series extremely flexible to benefit you in the long term from an investment that pays for itself.

Balancing with variable drives With HM universal balancing machines, you can combine different drives on one machine. Selection of a drive system is determined by the shape or your rotors. Underslung belt drives (BU) provide for smooth operation and are universally applicable and Universal-joint drives (U) for cases where a high drive power is required.

Advantages of HM

Universally applicable

Suitable for balancing cylindrical rotors with integral shaft journals and for balancing disc shaped rotors on balancing arbors.

Flexibly adaptable

Their modular design principle and a wide range of accessories make the machine highly flexible in setup and balancing.

Short changeover times

Hard-bearing design ensures quick and easy changeover from one rotor to the next.

User-friendly

Permanent calibration, ergonomic design and a logical operating sequence facilitate operation.

Comprehensive security package

A full range of safety equipment for all protection classes for safety without compromise.

Top-quality measurement technology

SCHENCK machine measuring instrumentation is easy to learn, fast and safe working and reduces operator faults.

HM series models From gears to turbines – HM balancing machines for small to large rotors

HM

Horizontal

Manual

HM 4 - HM 50

Balancing machines of the HM 4 and HM 40 series as well as HM 5 and HM 50 series enable precise balancing of a wide range of rotors with a maximum weight of 8 tons. Typical rotors include electric anchors and rollers, spindle shafts, turbochargers, crankshafts, fans, pump impellers, drive elements, tool holders, and gears.

- Maximum rotor weight: up to 8,000 kg

- Maximum rotor diameter: up to 1,600 mm (optional extension available)

- Bearing center distance: For belt drives up to 2,270 mm (optionally extendable)

- Bearing journal diameter: for bearing journals from 12 to 200 mm (optionally expandable)

HM

Horizontal

Manual

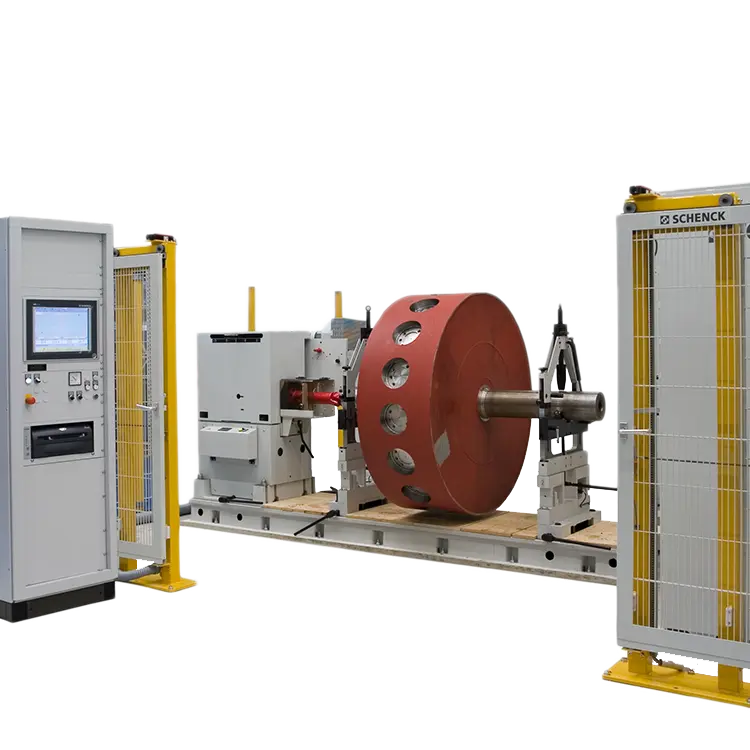

HM 6 - HM 80

The HM 6 and HM 60, HM 7 and HM 70, and HM 8 and HM 80 horizontal universal balancing machines are ideal for large, rigid, and elastic rotors with a maximum rotor weight of up to 250 tons. Typical applications include: blowers and fans for all industrial sectors, high- and low-speed rollers for the paper and film industry, electric squirrel-cage motors and generators for the electrical industry, and separators/centrifuges for water treatment.

- Maximum rotor weight: 12,000 kg (HM 6) up to 250,000 kg (HM 80)

- Maximum rotor diameter: 2,100 mm (HM 6) up to 3,600 mm (HM 80) (optionally extendable)

- Bearing center distance: Flexibly configurable from < 3,000 to > 15,000 mm

- Bearing journal diameter: for bearing journals from 40 to 320 mm (optionally expandable)

Worth knowing Facts, figures, and data about the modular universal balancing machines of the HM series

-

Special features

-

Schenck universal balancing machines of the HM series are ideal for single rotors and small series:

- Easy to operate – hard-bearing principle eliminates the need for calibration runs

- Balancing possible in two planes or separately according to static unbalance/moment unbalance.

- Storage of rotors on original or auxiliary shafts, on support rollers or in slide bearings/with mounted roller bearings.

- Angle adjustment display for belt drive

- Automatic measuring cycle with continuously adjustable values for start-up, measuring and braking times.

Expandable with numerous additional modules, e.g. for mass balancing.

-

Areas of application

-

HM 4 - HM 50

- Suitable for: roller-shaped rotors with their own shaft journals and disc-shaped rotors with auxiliary shafts

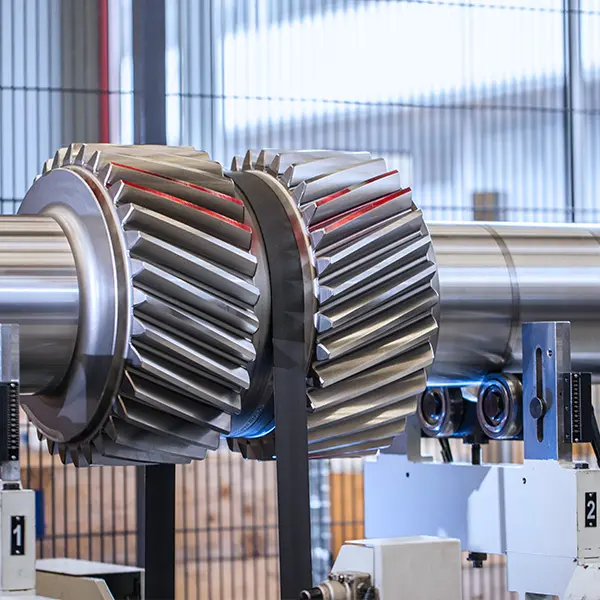

- Typical rotors/areas of application: Electric armature and rollers up to 8,000 kg, spindle shafts, turbochargers, crankshafts, fans, pump impellers, drive elements, tool holders, and gear wheels

HM 6 - HM80

- Suitable for: roller-shaped rotors with their own shaft journals and disc-shaped rotors with auxiliary shafts

- Typical rotors/areas of application: electric armature, rollers, and turbines up to 250 tons, spindle shafts, turbochargers, crankshafts, fans, pump impellers, drive elements, tool holders, and gear wheels

-

Protective device

-

The hazard posed by the rotor is decisive when choosing your protective device. Take into account the balancing speed, balancing method, and maximum possible impact energy. Protective devices for balancing machines are divided into five safety classes (0, A, B, C, D) according to ISO 21940-23. Class B or C protective devices are mainly required for HM balancing machines.

Select safety class B if there is a risk of injury:

- when touching the rotor,

- originating from parts of the drive

Select safety class C if it cannot be ruled out with certainty that parts may detach from the rotor.

We calculate the penetration potential for you based on the size, shape, hardness, and tangential velocity of a flying part and configure your protective device on this basis.

Unbalance measurement technology from Schenck

Schenck measuring systems for simple, precise, and safe balancing

All data at a glance

Modern measurement technology is at the heart of every Schenck balancing machine. With our CAB and SchenckOne unbalance measuring devices, you benefit from digital measurement processing for high accuracy, a clear unbalance display, and an ergonomic, easily accessible operating concept.

CAB 920 – innovative all-rounder

With our proven CAB 920 measuring system, balancing can be achieved with minimal training. This is ensured by the innovative operating concept with guided navigation. Do you have special requirements? CAB 920 can be expanded with additional functions and industry-specific solutions and adapted to your needs.

Gain a competitive edge with Schenck ONE

Schenck ONE is the leading software platform for balancing, supporting you in all work steps. It ensures error-free processes through intuitive operation, enables location-independent machine adjustment, and offers automatic software updates that you can perform at your convenience.