Fan & Blower

Balancing and diagnostic systems are crucial for fans and blowers in the automotive, industrial and home appliance sectors. They detect and correct unbalance and diagnose electrical and physical parameters. By using these systems, companies can reduce costs, increase the quality of their products and improve their energy efficiency.

State-of-the-art technology for efficient quality assurance

High-precision balancing technology for automotive and industrial applications Our range of balancing machines for fans and blowers offer flexible solutions for automotive and industrial applications. For automotive blowers, such as engine fans and interior fans, they enable precise static and dynamic unbalance measurement in one or two planes. They also ensure optimum balance and efficiency for industrial ventilation and air conditioning systems as well as household appliances. The machines impress with their high precision, simple operation and wide range of applications.

Individual control and diagnostics Our balancing machines for fans and blowers offer maximum flexibility in terms of functionality. The motors are controlled individually according to the customer's requirements and can include various technologies: PWM, LIN or CAN bus as well as voltage control via DC and AC is possible. All fan balancing and diagnostic machines record a wide range of mechanical and electrical parameters, such as current voltage, speed, direction of rotation, fan run-out and vibrations. These diagnostic systems can be optionally expanded with additional functions, according to customers specifications.

Flexible fan mounts Flexible realization of different fan mounts, whether in the shroud, only as a fan with a motor, or other variants, are possible. We customize the size, measuring functions and requirements to ensure precise and efficient balancing, both for single and double blowers.

Advantages of balancing and diagnostic machines for fans and blowers

Precise measurement

Measurement of current, voltage, speed, direction of rotation and axial run-out.

Sensors

A sensor system can be implemented as an option.

Diagnostic software

Highly accurate diagnostic software for simple operation and maximum precision

Storage

All measurements are stored to ensure optimal traceability during production.

Versions of the Schenck balancing and diagnostic machines Balancing and diagnostic system for complete blowers with free design as 1-station machine or 2-station machine.

Fan & Blower

Balancing and diagnostics

horizontal

one-station

two-station

REJH

The REJH horizontal balancing and diagnostic system is suitable for unbalance measurement in the series production of complete vehicle interior blowers. It is suitable for measuring static and dynamic unbalance in both rotor planes to optimize unbalance correction. Other possible test and diagnostic procedures include analyzing the motor current and voltage, vibroacoustic noise testing (VAD) and measuring the direction of rotation and speed. These parameters can be flexibly expanded according to customer requirements. The REJH offers a flexible approach and easy retrofitting for a wide range of fan types and motor diameters.

- Test item: Complete vehicle blower with built-in motor

- Test procedure: VAD, signal analysis, electrical/mechanical and unbalance measurement

- Cycle time: 20 to 50 s, depending on the blower type, depending on the station

- Changeover time: less than 5 min

Fan & Blower

Balancing & Diagnostics

Vertical

One-station

Two-station

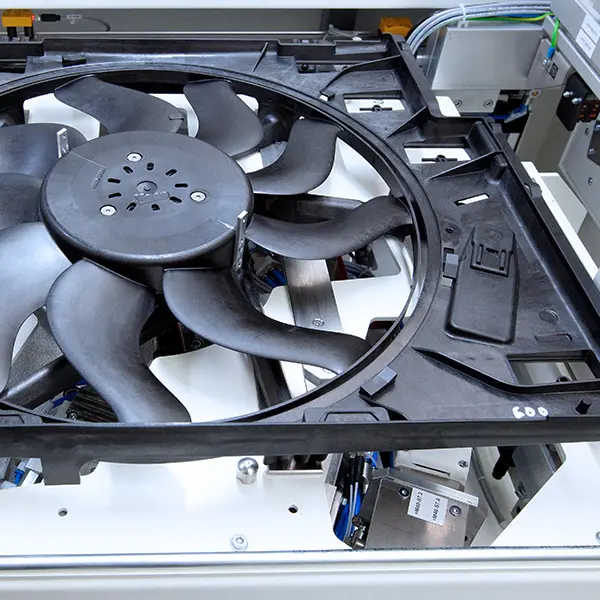

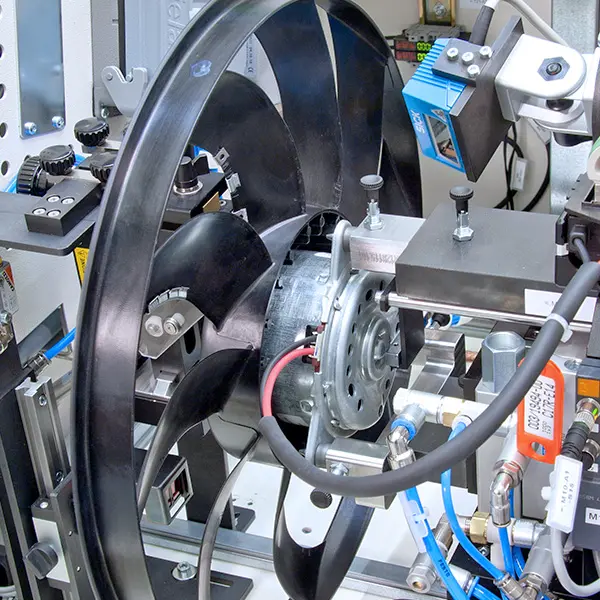

REJS

The REJS is the vertical Schenck balancing machine for engine-cooling fan assemblies and complete units. The semi-automatic machine with manual fan loading and manual correction can also be used for double fan modules if required. Correction is carried out by adding metal weight clips to the fan blades. The REJS offers the option of clamping complete fan modules with frame as well as just the drive with fan wheel. The tools can be changed in just a few minutes when the machine is in use.

- Test item: Engine cooling fan

- Testing procedure: VAD. Signal analysis, electrical/mechanical and unbalance measurement

- Cycle time: 30 to 75 s, depending on blower type, depending on station

- Optional: 2-station machine - Both stations measure independently of each other

Fan & Blower

Balacing & Diagnostic

Gas heating appliance

Two-planes

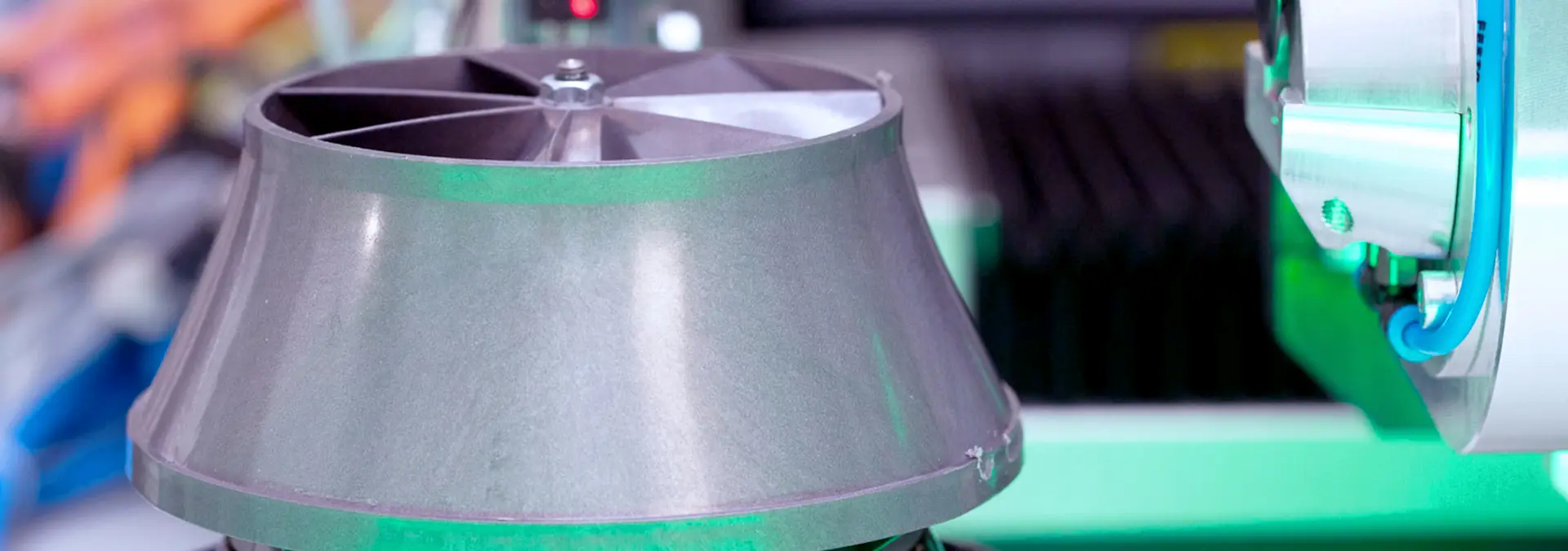

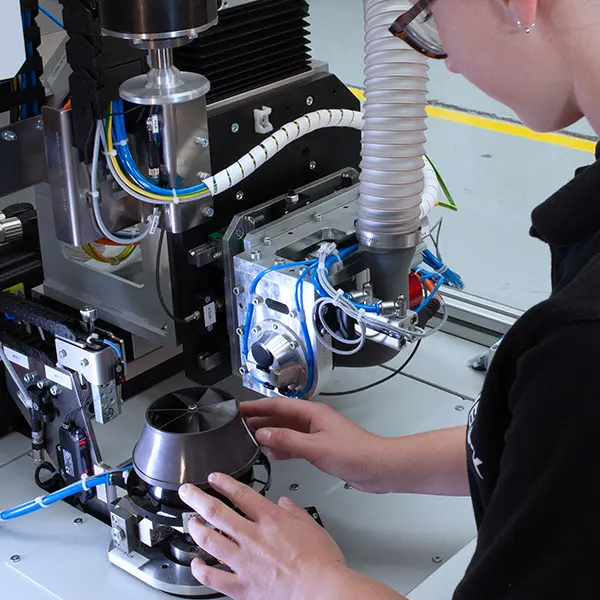

REJV

The REJV balancing and diagnostic machine has been specially developed for use with gas heating appliances. It is a hand-loaded machine combined with an automatic balancing unit to ensure precise and efficient machining. The machine performs corrections in two planes to ensure optimum balancing. The unbalance of the fan is corrected by removing material with a milling unit. The cycle time depends on the milling steps.

- Test item: Fans for gas heaters

- Test procedure: Signal analysis unbalance measurement

- Cycle time: 45 to 50 s, depending on the blower type, depending on the station

- Correction: Automatically by milling

Measurable parameters

All diagnostic and balancing machines in the REJ series record the following parameters:

- Current

- Voltage

- Rotational speed

- Direction of rotation

- Static unbalance

- Dynamic unbalance

- Axial and radial runout of the fan

- Vibration detection VAD: Checking the NVH characteristics of the running fan

- Fans can be controlled via LIN bus, PWM or AC/DC