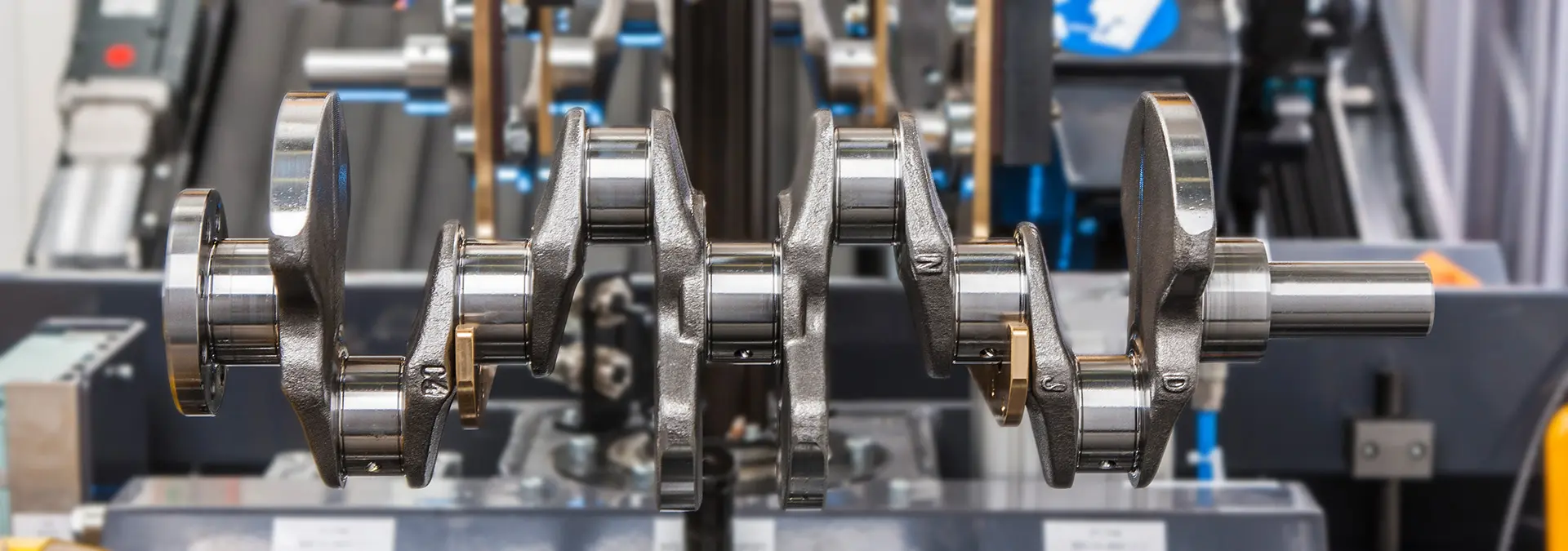

Crankshafts

Our crankshaft balancing machines offer you the optimal solution for every requirement – from fully automated integration into series production to manual quality control for balancing finished crankshafts and mass centering blanks.

Perfection for every step of the process Maximum precision

Precision that pays off. Our machines enable you to comply with and document even the tightest tolerances. Your entire process benefits from this advantage: The powerful balancing calculation of the CAB 950 minimizes the number of balancing bores required and shortens cycle times, even in complex balancing situations. Often, a single balancing step is sufficient to achieve a perfectly balanced crankshaft. This extends tool life and ultimately improves your cost per unit significantly.

Productivity without compromise Our high-end CAB950 measuring device offers comprehensive solutions for complex crankshafts and challenging unbalance compensation conditions. It takes into account numerous parameters such as prohibited zones, various counterweight geometries, different tools and drill geometries, and allowances for components to be attached. Based on evaluation of incoming unbalances the instrument can calculate bias values for the centering operation. By using calibrated standards from our accredited testing laboratory and standardized testing procedures, you can easily verify the accuracy of the imbalance measurement and the quality of the balancing.

Versatile, in series production

or separately

Manual, semi-automatic, or fully automatic? The choice is yours. Integrate our balancing machines as single-station or dual-station machines into series production or use them separately for balancing checks and repairs.

Maximum flexibility thanks to

easy conversion

Flexibility guaranteed. In the rapidly changing automotive industry, all process steps must meet increasing demands for efficiency, ease of use, and precision. We understand these challenges and have designed our solutions accordingly. Our answer: high flexibility, low space requirements, optimized energy consumption, easy maintenance, long service life, and low maintenance costs.

Advantages of our balancing machines for crankshafts

High flexibility

Suitable for measuring unbalance and centering a wide variety of crankshafts.

Manual to fully automatic

Fully integrated, semi-integrated, or purely manual loading and unloading of crankshafts possible.

Wide range of solutions

Various configurations available for different workpiece dimensions and productivity requirements.

Powerful measurement software

Efficient processes and precise results thanks to the CAB 950 measuring system. The accurate and efficient calculation of unbalance compensation and the specialized compensation calculation can handle even difficult cases.

Easy integration

Can be integrated into automatic production lines with minimal space requirements.

Short cycle times

Thanks to precise measurements and efficient compensation calculations, the shortest possible processing times are achieved, which increases productivity and is ideal for high demands on cycle times and quality.

Design of our machines for your crankshaft Robust systems with modern equipment for precise unbalance measurement.

Crankshafts

Fully automatic

balancing machine

single-station machine

320 SBRK-C, 520 SBRK-C

Ideal for medium to large series production: Our 320 SBRK-C and 520 SBRK-C balancing machines offer fully automatic measurement and compensation of unbalance. These compact single-station machines allow manual or automatic loading. The oscillating frame with robust hook drive and slide bearings ensures operating-like measuring conditions, reduces surface load during drilling, and protects the main bearings. Drilling with minimum quantity lubrication shortens drilling times and improves tool life. Asymmetrical crankshafts can be balanced without master rings. The machines in the SBRK-C series are available in various sizes for passenger car and light commercial vehicle crankshafts as well as for medium and heavy commercial vehicle crankshafts.

- Maximum rotor weight: 8 to 160 kg

- Total length: up to 1.400 mm

- Maximum bearing distance: up to 1.100 mm

- Main bearing diameter: up to 160 mm

Crankshafts

Fully automatic

balancing machine

multi-station machine

CENO

The CENO automatic balancing machine is particularly compact and ideal for small and medium-sized crankshafts weighing up to 20 kg. With standardized interfaces, it can be easily integrated into customer loading and unloading systems, even retrospectively. The CENO has a precise balancing unit with final drive that can also balance asymmetrical crankshafts without master ring weights. Unbalance is compensated by optimized polar drilling into the counterweights. Thanks to minimum quantity lubrication, no additional coolant or lubricant is required, which allows the workpieces to be further processed without cleaning. In addition, the CENO features energy-efficient drives that consume about 25% less energy than comparable solutions.

- Maximum rotor weight: up to 20 kg

- Total length: up to 600 mm

- Distance between shaft center and drive end: 100 to 240 mm

- Main bearing diameter: 40 to 70 mm

Crankshafts

Fully automatic

balancing machine

two-station machine

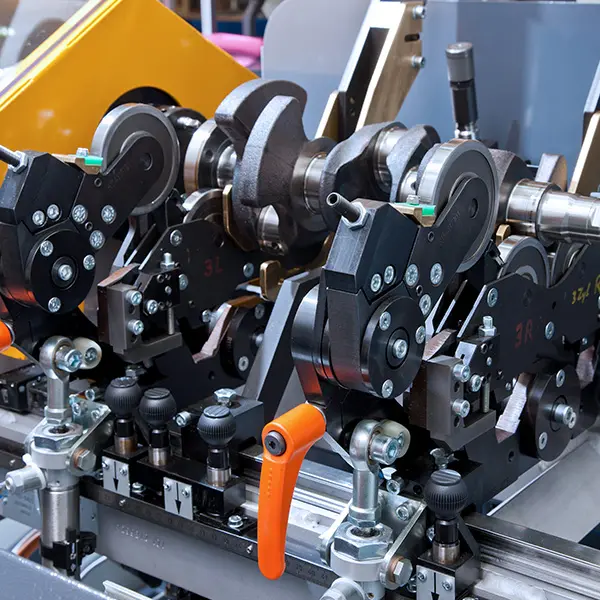

Bario

Bario is a fully automatic and flexible 2-station balancing machine for the series production of symmetrical and asymmetrical passenger car crankshafts. The precision balancing unit allows asymmetrical crankshafts to be measured without the need to install master rings. Automatic unbalance compensation is achieved by drilling with minimum quantity lubrication. Particularly advantageous for the high cycle time and quality requirements in the automotive industry: The machine can be converted to other crankshaft types in a very short time.

- Maximum rotor weight: up to 30 kg

- Maximum lenght: up to 650 mm

- Main bearing diameter: 40 to 70 mm

- Additional features: Optimized ergonomics, automatic tool changer (optional), flexible chip disposal, and layout

Crankshafts

Fully automatic

balancing machine

compact

energy efficient

KBTK-C

Our KBTK-C is particularly powerful when working with large asymmetrical crankshafts. With a hook drive balancing unit with an externally rotating hook for attachment to the crankpin and the option of storing the crankshafts in rollers or bearing shells, the KBTK-C offers maximum precision when measuring large asymmetrical crankshafts and large values for master ring masses to be simulated. For unbalance compensation in one or two-step processes, the machine has a robust and powerful two-spindle drilling unit. This allows two drilling diameters to be combined as desired and without any loss of time in the compensation process.

- Maximum rotor weight: up to 50 kg

- Total length: up to 790 mm

- Main bearing diameter: 40 to 80 mm

- Maximum drilling diameter: up to 25 mm

Crankshafts

Manual

balancing machine

two-station machine

300 EBTK, 310 EBTK, 320 EBTK

Compact, flexible, and precise: Our two-station balancing machines are ideal for small to medium-sized series production or repair applications. They offer various balancing units that can be selected depending on the foreseen crankshaft types. With their clutch-free roller drive or hook drive balancing unit, they are optimized for unbalanced crankshafts. Manual loading and manual transport between the measuring and balancing stations ensure versatile application possibilities without compromising precise positioning during the unbalance correction. Measurement and control run are performed automatically, while balancing is achieved through precise drilling into the counterweights on a separate drilling station. A second balancing step is possible if required.

- Maximum rotor weight: 6 to 35 kg

- Total length: 280 to 790 mm

- Maximum bearing spacing: up to 650 mm

- Main bearing diameter: 40 to 80 mm

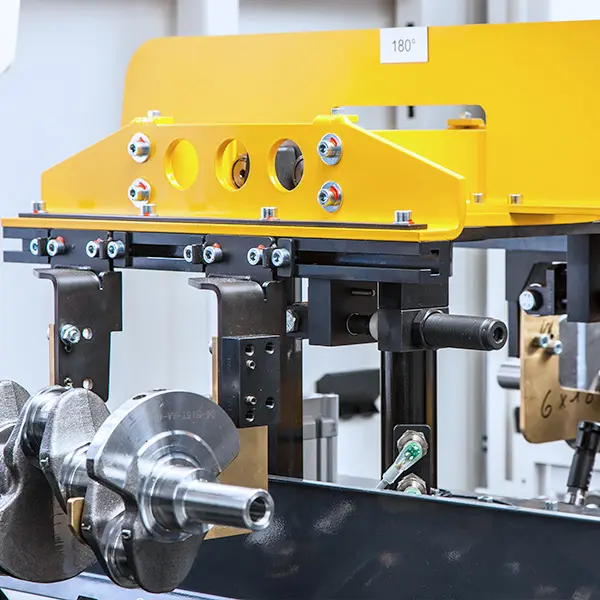

Crankshafts

Fully automatic

mass-centering machine

flexible

400 SBRZ, 400 MBRZ, 600 SBRZ, 600 MBRZ

A special clamping device enables precise measurement of the eccentricity of raw crankshafts, which ensures accurate determination of the position of the axis of inertia. Thanks to our many years of experience, we are also able to reliably mass-centering asymmetrical crankshafts. We offer two solutions for this process:

400MBRZ and 600MBRZ series: Measurement of eccentricity and transmission of coordinates for centering for the subsequent operation. Particularly suitable for high productivity with a smaller range of types, requires no pre-processing, and enables the combination of different processing steps depending on the machine concept.

400SBRZ and 600SBRZ series: Measurement of eccentricity and insertion of centering holes in an optimized position. Suitable for a wide variety of types, requires only cutting to length as pre-processing.

The machines are easy to convert and can be loaded automatically or manually with the aid of lifting equipment.

- Maximum rotor weight: up to 200 kg

- Maximum rotor diameter: 220 to 320 mm

- Length: 360 to 1.500 mm

- Main bearing diameter: 45 to 180 mm

Crankshafts

Manual

inspection machine

MBRK series

For maximum precision in quality assurance during inspection or production, Schenck inspection machines offer quality control for crankshafts weighing up to 250 kg. With a horizontal rotor axis, a clutch-free roller or spindle drive, and a highly sensitive measuring unit, they enable precise detection of unbalance in two planes. Optionally expandable with a correction unit. In desired configuration suitable for determing centering biases and, thanks to their expandability, can be flexibly integrated into your production line.

- Maximum rotor weight: up to 250 kg

- Maximum length: up to 2.000 mm

- Maximum bearing spacing: up to 1340 mm

- Main bearing diameter: up to 130 mm

Design & planning for your production We support you in the development and planning of your systems for the precise manufacture of crankshafts – from the initial idea to series production.

Worth knowing Figures, data, and facts about our inspection and balancing machines for crankshafts.

-

Balancing machines and measuring devices for crankshafts from Schenck

-

To meet the many different requirements for crankshaft balancing, Schenck offers a wide range of machines that can be flexibly adapted to your needs.

- High-precision control of unbalance in symmetrical and asymmetrical crankshafts and blanks

- Machines in various sizes for rotors weighing between 6 and 250 kg

- Wide range of single and multi-station machines for unbalance control, including fully automated machines for unbalance measurement and compensation

- Various loading and transport options, from manual to fully automatic

- Integrated in all machines: High-end Cab 950 software with intuitive touchscreen operation and precise balancing calculations

-

Areas of application

-

MBRK series

- Suitable for: finished crankshafts weighing between 6 and 35 kg and car and truck crankshafts of various sizes weighing between 7 and 250 kg.

- Area of application: In inspection or production for quality control of balancing machines. Can be expanded with a balancing unit in production for checking the production quality of centered crankshaft blanks and/or finished crankshafts and for determining centering allowances. Expandable thanks to modular design.

300 EBTK, 310 EBTK, 320 EBTK

- Suitable for: Measuring and balancing the unbalance of finished crankshafts from passenger cars and light commercial vehicles between 6 and 35 kg.

- Area of application: For small and medium series in production or as a repair balancing machine.

320 SBRK-C, 520 SBRK-C, 720 SBRK-C

- Suitable for: Measuring and balancing the unbalance of finished crankshafts from passenger cars and commercial vehicles weighing between 8 and 160 kg.

- Area of application: Medium and large series production.

400 SBRZ, 400 MBRZ, 600 SBRZ, 600 MBRZ

- Suitable for: Balancing centering of crankshaft blanks weighing 7 to 200kg, processing of symmetrical and asymmetrical designs.

- Application: Use by the manufacturer or processor of the crankshaft, in the production of medium or large series.

Bario

- Suitable for: Fully automatic and flexible 2-station balancing machine for series production of symmetrical and asymmetrical car crankshafts up to 30 kg.

- Area of application: Ideally suited to the high demands on cycle times and quality in the automotive industry.

CENO

- Suitable for: The CENO is a compact automatic balancing machine for small and medium-sized crankshafts with a maximum weight of 20 kg.

- Area of application: easy integration into customer loading and unloading systems thanks to standardized interfaces.

-

Special features

-

MBRK series

- Measurement of unbalance in two planes, relative to the outer counterweights

- onversion of unbalance values to other planes, automatically or manually controlled

- Measuring system for unbalance measurement or optimal balancing calculation – with software packages for component or optimized balancing, user guidance, diagnostic programs, error displays, statistics program, and printer connection

- Horizontal rotor axis and a balancing unit, as also used in transfer balancing machines

- Clutch-free roller drive or spindle drive with hook driver

- Welded machine bed, safety guard, and sliding hood included as standard

- Horizontal rotor axis and robust, subcritical balancing unit

- Belt drive for the crankshaft and drive shaft for the cage

- Depending on the application, storage of the crankshaft between tips, in a cage, or in roller bearings

- Universal belt drive or driven cage, no drivers required

300 EBTK, 310 EBTK, 320 EBTK

- Two-station machine with separate measuring and balancing station

- Measuring station with clutch-free roller drive or hook drive balance for unbalanced crankshafts

- Balancing station with positioning device and electromechanical drilling device

- Unbalance compensation by drilling into the counterweights in one or two balancing steps on a separate drilling stand (balancing stand)

320 SBRK-C, 520 SBRK-C, 720 SBRK-C

- Compact single-station machine with stable weight frame and minimum quantity lubricated multiple bearings

- Hook drive for driving the crankshafts at the stroke bearing journal

- Drilling portal arranged at an angle to the rear with NC-controlled slide drilling unit

- Measurement and compensation of unbalance in the same station, resulting in low effort

- Operating-like measuring conditions thanks to oscillating frame with multiple slide bearings, low surface load during drilling and protection of the main bearings

- Shorter drilling times and longer tool life thanks to drilling with minimum quantity lubrication

- Turning in of the crankshafts, movement of the drilling unit and control of the drilling depth via the measuring station

400 SBRZ, 400 MBRZ, 600 SBRZ, 600 MBRZ

- Loading via automatic conveyor systems or manually using lifting equipment

- Can be integrated into production lines and transfer systems, variable processing scope

- Particularly suitable for variable crankshafts programs thanks to flexible machine design

- Weight frame support on machine bed via round bar springs

- Two slide units mounted on the weight frame with integrated external pulleys mounted in precision bearings, each with two adjustment gears

- Hydraulic quill drilling units or electromechanical slide drilling units for drilling the centering holes, either in the measuring station, in a separate centering station, or in the machining center

Bario

- Measurement of asymmetrical crankshafts without the installation of master rings in the precision balancing unit

- Automatic unbalance compensation by drilling with minimum quantity lubrication

- Monoblock design

- Modular balancing unit

- End or pin drive for balancing symmetrical and asymmetrical crankshafts

- Roller drive for balancing symmetrical crankshafts

- Drilling compensation with minimum quantity lubrication (MQL)

- Internal stroke-rotation transport

- Polar-optimized unbalance compensation with Schenck optimization algorithm

CENO

- Space-saving monoblock design

- Balancing of asymmetrical crankshafts without master ring weights thanks to high-precision balancing unit with final drive

- Unbalance compensation through optimized polar drilling into the counterweights

- Integrated rotary transfer for internal exchange of crankshafts

- Minimal quantity lubrication eliminates the need for coolant supply and treatment: no pumps, no cooling, no filtering, no costly environmentally friendly disposal

- Approximately 25% lower energy consumption than comparable solutions

- Easily accessible chip chart under the machine bed colletcs the chips produced during the unbalance compensation – optionally with fill level detection

CAB 950

The measuring device for series production – with simple operation, highly accurate measurement recording, and precise compensation calculation.

Precise mechanics and measurement technology

CAB 950 is not just a measuring device, but an intuitive human-machine interface (HMI). With easy access to all the functions you need in production—from optimal balance calculation and precise balance control to static process functions and modern CAB measurement technology for maximum precision in unbalance balancing.

A wide range of functions for maximum accuracy

Numerous standard functions ensure even greater accuracy when balancing crankshafts: for example, polar-optimized compensation, measurement of environmental interference, and many more.

Support for quality management

CAB 950 offers you online statistics with unbalance and process analysis as well as a certified Q-DAS interface (AQDEF) for your quality management.