Wheel Assembly Lines

Schenck provides equipment for manufacturing and testing wheels.

Whether you need a single machine or a fully automated complete system, Schenck optimizes your wheel assembly with highly specialized solutions for every wheel line and will turn your specifications into customized, high-performance solutions.

Pure performance for the assembly and testing of complete wheels

Wheel assembly lines for every requirement Schenck's wheel assembly lines ensure highly efficient assembly and testing of complete wheels thanks to their high precision and innovative technology. From semi-automatic and fully automatic to robot-assisted solutions, we implement your production specifications in various stages of expansion and in the ideal way for you.

Customized efficiency through powerful individual systems Our modular wheel and tire machines can be integrated into a wheel assembly line and also be used as a standalone system to expand existing production facilities. Starting with the core process of assembly, pressure filling, and balancing for small to medium quantities, through to high-end solutions for maximum flexibility with various testing processes, wheel optimization and specifically short cycle times, Schenck offers you optimal support for every step of the way to the finished complete wheel.

The right solution for every requirement We support your complete wheel assembly with individual machines or fully automated complete systems. Our solutions include automatic valve assembly, automatic mounting of tires on rims with matching, filling with air pressure, and optimizing the tire fit on the rim. We offer measuring dynamic unbalance, manual or fully automatic unbalance compensation, and reading DOT codes and designer recognition. We also provide the integration of wheel uniformity measuring machines (Uniformity) for complete assembly systems.

Advantages of our machines for your complete wheel

Wide range of wheels

Machines for tires from 14” to 25” and all rim designs

Short cycle time

Short cycle times thanks to high efficiency, whether manual, semi-automatic, or fully automatic

Impressive precision

High-precision, fully manufactured complete wheels: from individual parts to entire wheels

Maximum flexibility

Solutions for every requirement and every tire size – semi-automatic or fully automatic, single machine or complete wheel system

Maintenance-efficient

High availability with low maintenance requirements with support provided by maintenance contracts, remote maintenance, and a 24-hour hotline

Energy efficient

Constructive solutions for reducing energy consumption featuring sustainable components with a long service life

Descriptions of our wheel assembly machines High-performance systems for small and large challenges – as individual systems or complete lines.

Linee di assemblaggio ruote

Linie do montażu kół

Wheel Assembly Lines

Fully automatic

Semi automatic

Automatic valve screwing

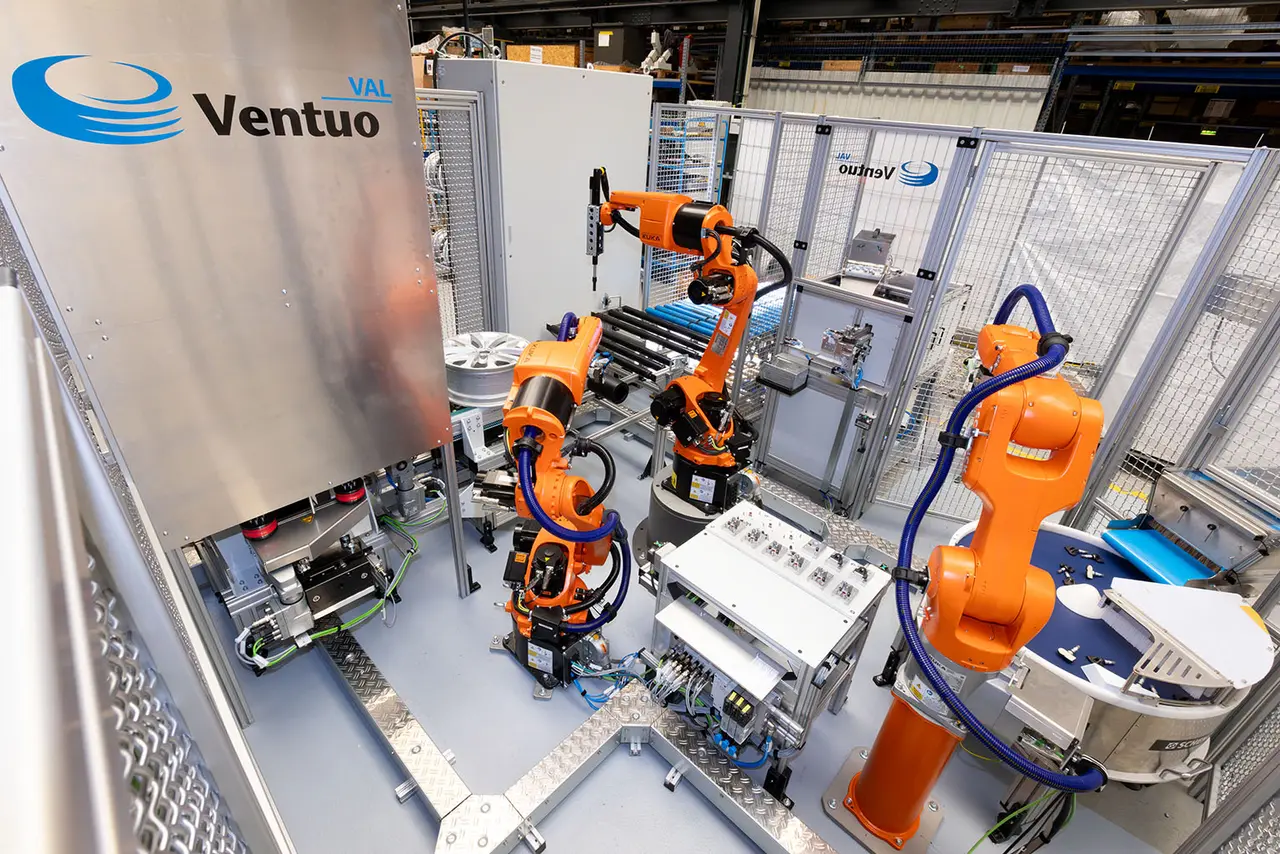

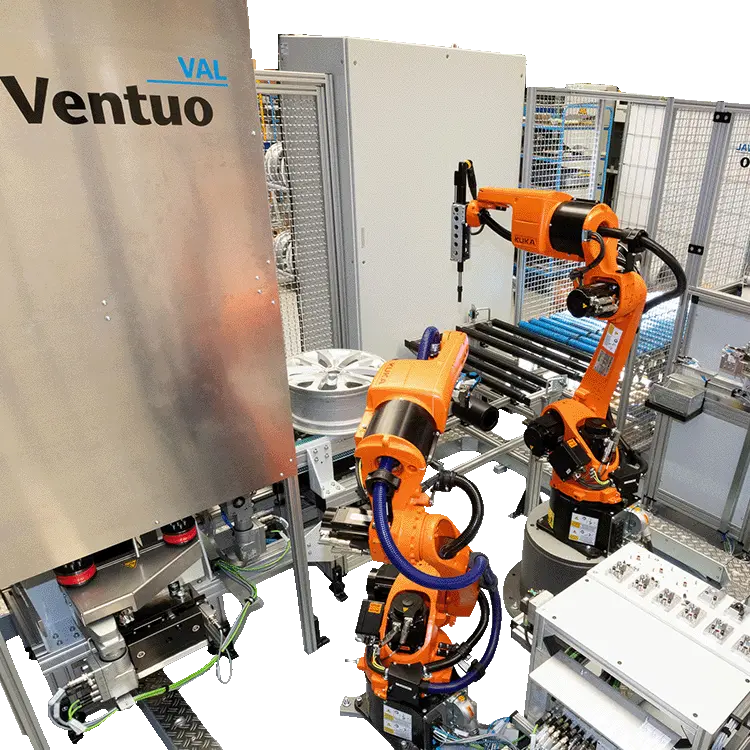

Ventuo Val - NEW!

Ventuo Val is our new automation solution for RDK screw valves, RDK snap-in valves, and rubber valves. The machine processes more than 300 parts per hour and can handle rims ranging in size from 15" to 25" without retooling. The modular system enables the processing of different valve types and rim geometries without time-consuming teaching and is flexibly adaptable to different layout specifications and is expandable using robotics, innovative vision systems, and AI-based algorithms.

- Maximum complete wheel weight: up to 50 kg

- Rim size: 15″ up to 25″

- Rim width: 5″ up to 14″

- Number of wheel-tire combinations: 9.999

Linie do montażu kół

Linee di assemblaggio ruote

Wheel Assembly Lines

Fully automatic

Semi automatic

Wheel mounting machines

Ventuo Mount

Ventuo Mount wheel mounting machines offer maximum efficiency for semi-automatic and fully automatic mounting of tires on rims, including the mounting of run-flat tires, UHP tires, or complete wheels for vans. Various individual functions, such as plausibility checks of the tires and rims fed into the machine, mounting torque monitoring, valve detection and positioning, or automatic soap application for tires and rims, make the mounting station a fully automatic complete system that meets all your requirements.

- Maximum complete wheel weight: up to 50 kg

- Total wheel outer diameter: 550 to 900 mm

- Rim diameter: 14" to 25"

- Number of wheel-tire combinations: 9.999

Linie do montażu kół

Linee di assemblaggio ruote

Wheel Assembly Lines

Fully automatic

Tire filling bells

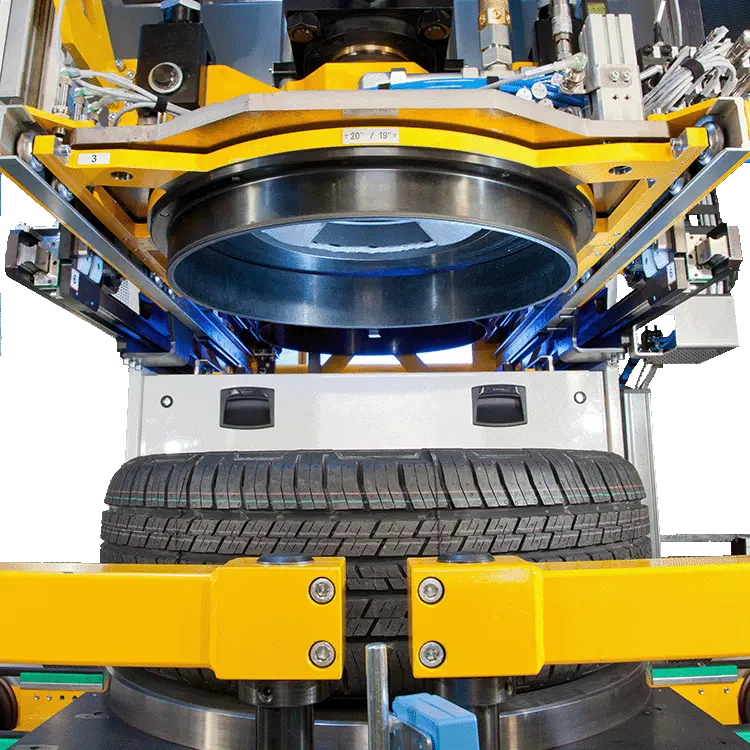

Ventuo Inf

The Ventuo Inf series machines are designed for efficient filling of car tires, regardless of rim design for tire sizes from 14" to 25". The tire filling process using a filling bell takes place without contact with the rim design side. An individual filling ring configuration is available for maximum application flexibility. The neutral exchange of filling rings in mixed operation occurs through our patented filling ring magazine without affecting the cycle time. The fully automatic filling bell ensures maximum filling accuracy and the shortest cycle times.

A patented test standard allows you to check the machine capability and filling accuracy without being influenced by the tire/temperature properties.

- Maximum complete wheel weight: up to 50 kg

- Complete wheel outer diameter: 550 to 900 mm

- Rim diameter: 14'' to 25''

- Rim width: 3,5'' to 14''

Linie do montażu kół

Linee di assemblaggio ruote

Wheel Assembly Lines

Fully automatic

Wheel balancing machines

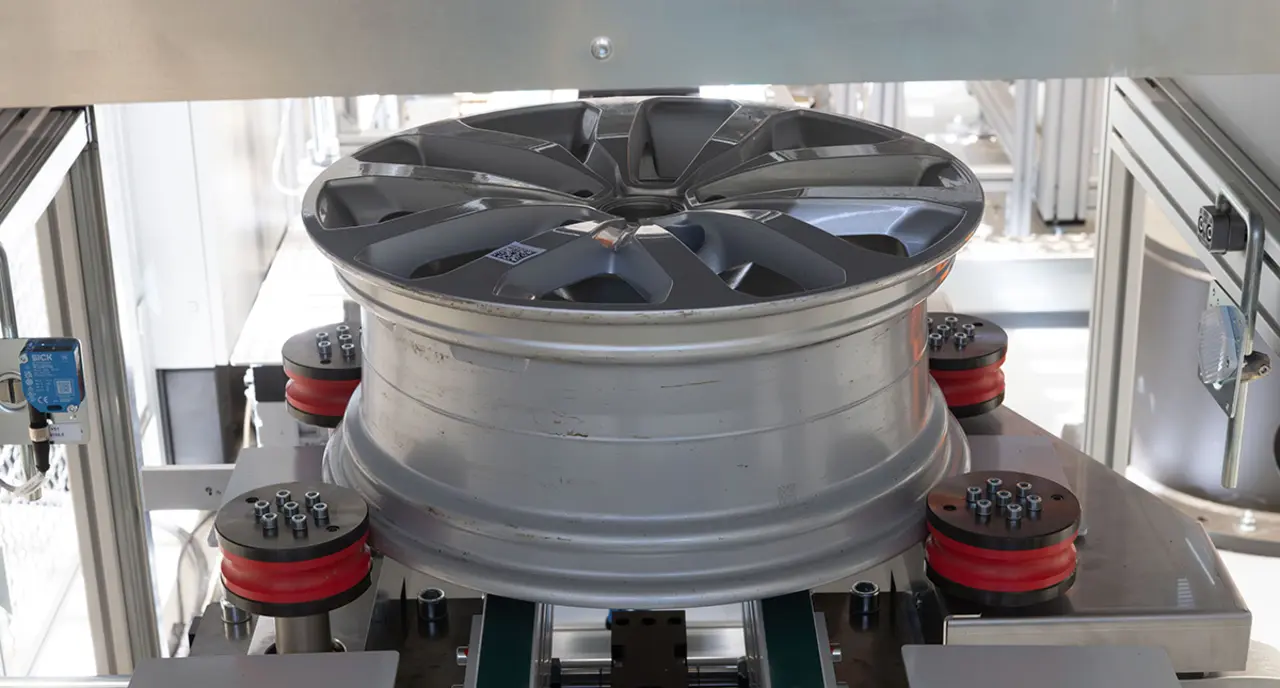

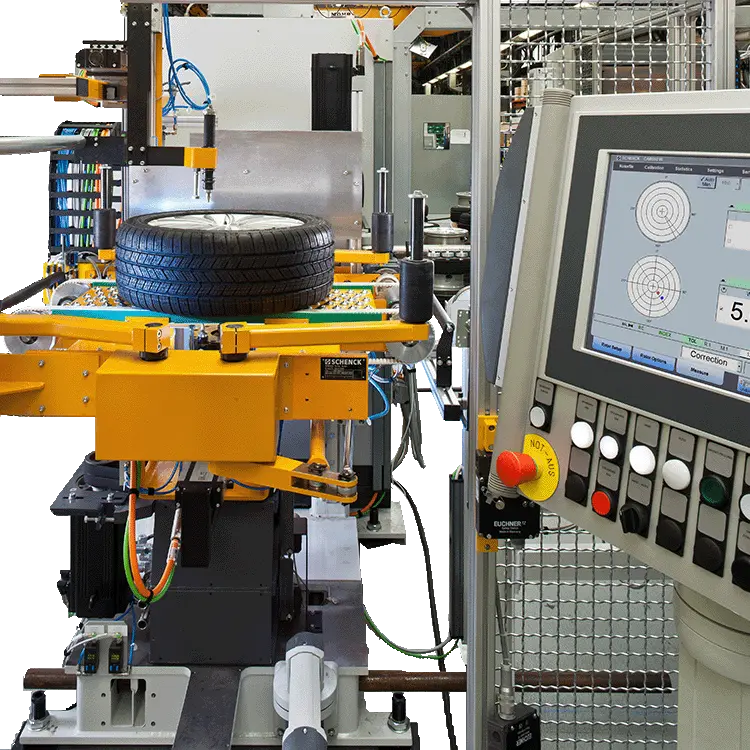

Ventuo Bal

Our fully automatic wheel balancing machines from the Ventuo Bal series measure the static and dynamic unbalance of complete car wheels and rims in a working range from 14'' to 25''. They measure the unbalance and calculate the necessary balancing procedures for the optimal balancing process, thereby, achieving the smallest residual unbalances of the complete wheel, and, when in “control measurement” mode, determine the residual unbalances after balancing has been completed. Your advantages are the high stability of the measuring system without interference with cycle times of less than 10 s. Our Ventuo Bal is the basis for unbalance testing in the rim manufacturing process and considers advance values for different valve types when determining residual unbalance.

- Maximum complete wheel weight: up to 50 kg

- Total wheel outer diameter: 550 to 900 mm

- Rim diameter: 14'' to 25''

- Rim width: 3,5'' to 14''

Linie do montażu kół

Linee di assemblaggio ruote

Wheel Assembly Lines

Fully automatic

Manual

Control balancing machine

Ventuo Cor

Ventuo Cor balancing solutions offer manual and fully automatic balancing systems for wheel manufacturing. Our balancing stations are an integral part of a wheel balancing machine and all known balancing weights can be processed in these stations. In manual balancing, the operator attaches the weights to the balancing planes supported by the wheel alignment function for ergonomic balancing in short cycle times. Fully automatic systems apply adhesive, or two-piece clamping weights, reliably in the corresponding balancing planes. When applying adhesive roller weights, these are cut to the exact length or weight by a cutting device and pressed onto the entire wheel surface by an application hand. The exact positioning of the balancing weights ensures low residual unbalance and smooth running of the complete wheel.

- Maximum complete wheel weight: up to 50 kg

- Total wheel outer diameter: 550 to 900 mm

- Rim diameter: 14'' to 25''

- Rim width: 3,5'' to 14''

Consulting & planning for your tire line We support you in the development and planning of individual systems and production lines tailored to your requirements or local conditions – from the initial idea to the finished complete wheel. Feel free to contact us!

Schenck complete wheel line

Components of Schenck complete tire mounting systems Optimized processes through technical perfection.

-

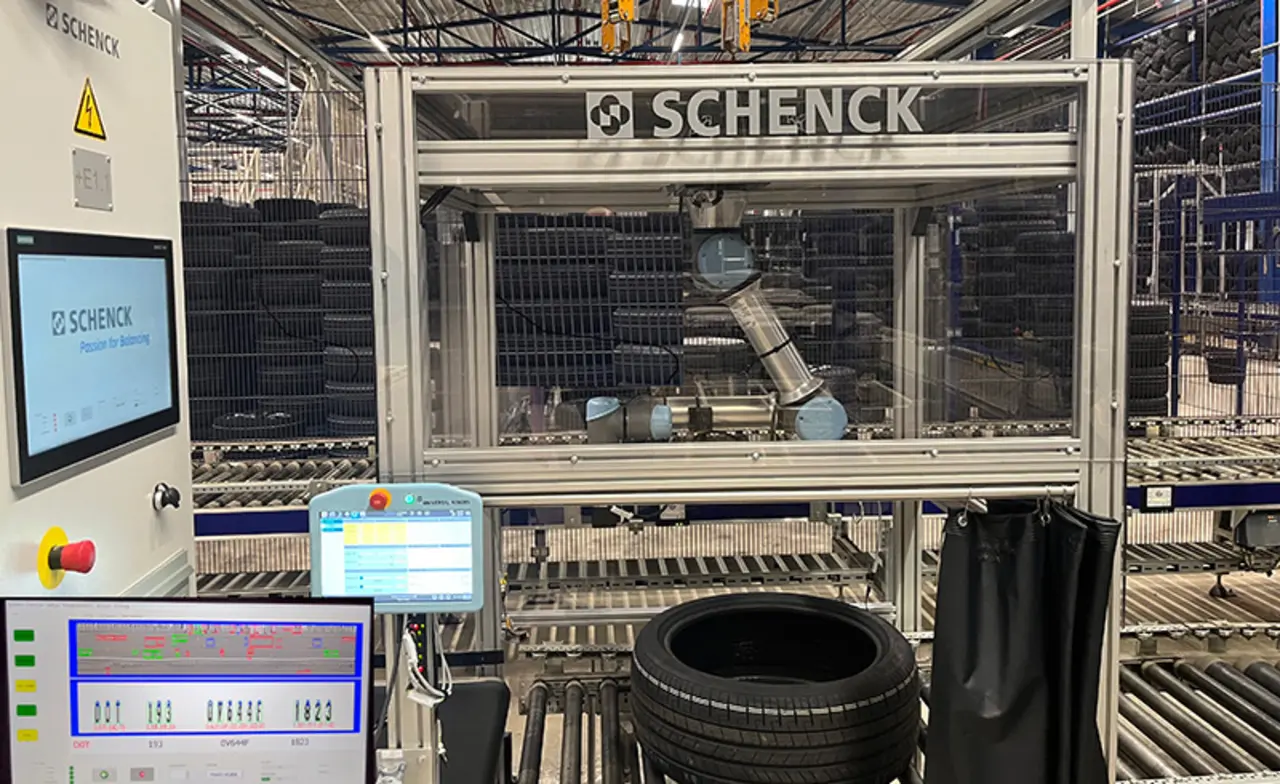

Component recognition, plausibility check, and DOT CODE reading

-

If production lines must process a wide variety of variants and still ensure that the permissible installation periods for components are adhered to, the components are usually checked or inspected using additional systems in the feed area of wheel production lines.

Schenck supplies the required fully automatic machines for rim design recognition or for reading the tire DOT code, and simultaneously an incoming inspection can be carried out and defective parts are ejected before they enter the production process.Our fully automatic machines offer:

- Rim design recognition

- Tire DOT code reading

- Tire production code reading and verification

- QR code reading on rims

- Tire barcode reading

- Wheel assembly recognition and plausibility check

-

Valve assembly – NEW!

-

The Ventuo Val offers you new ways in an efficient, state-of-the-art solution for automatic valve assembly for fully automated rim feeding on wheel production lines to automatically process RDK screw valves, RDK snap-in valves, and rubber valves. The heart of the system is the assembly station, where two collaborating robots perform the assembly and screwdriving process. A special gripping system precisely inserts the valves into the valve bore.

- Automatic mixing mode for at least 300 parts per hour

- Processing of rims in sizes 15" to 25" and rim widths from 5" to 14" without retooling

- Modular system for different valve types and rim geometries

- Efficient system without time-consuming teaching of wheel types

- Reliable measurement of the valve bore to compensate for geometric manufacturing tolerances

- Safe mounting, screwing, and attachment of wheel electronics according to manufacturer specifications

- Process data for quality assurance available via network connection

- Flexible adaptation to different layout specifications and future expansions

Further Advantages:

- Use of robotic, innovative vision systems, and AI-based recognition and evaluation algorithms

- Innovative feeding of RDC modules in loose arrangement with bulk material bunker and robot-guided gripping system

- Flexibility in automatic mixed operation thanks to multiple feeding systems

- Cap nuts are fed via vibrating conveyor and bunker system

- Integrated drawer system for economical provision of low-runner valves

-

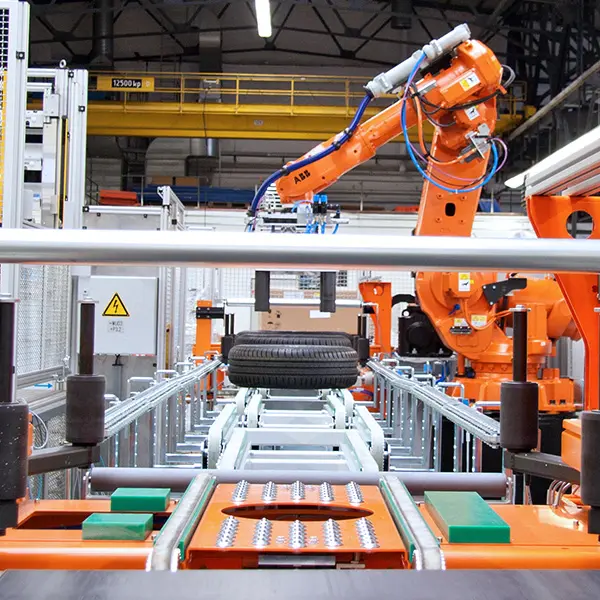

Wheel mounting machines

-

To ensure that tires are mounted gently depending on the tire type, we use highly flexible tools and monitor the parameters throughout the entire mounting process. Thanks to traceable process parameters and tool settings, our wheel mounting machines ensure flawless results regularly as part of an automatic wheel mounting line.

Our fully automatic machines offer:

- Flexible coverage of the working area from 14" to 25" in mixed operation

- Type-specific adjustable mounting station for the assembly of standard tires, run-flat and UHP tires, compact emergency tires, or commercial car tires

- Automatic plausibility check of the supplied complete wheel components for active misassembly detection

- Reliable application of lubricant to the rim and tire using a spray system with flow monitoring

- TPMS valve detection and positioning to prevent valve damage during mounting

- 4-point rim clamping for secure and gentle holding of the disc wheel during the mounting process

- Gentle tire mounting thanks to type-specific mounting procedures

- Special Schenck mounting tool with patented automatic radius adjustment of the bead deflector

- Continuous monitoring of the mounting torque with type-dependent limit value specification and graphical representation of the torque curve

Our semi-automatic machines offer:

- Ergonomic, manual loading concept

- Manual application of soap solution

- Compact design for reduced space requirements

- Machine is suitable for mounting run-flat tires

- Electromechanical adjustment and actuation of the mounting tools

- Servo control allows clear parameter documentation of the mounting programs

- Gentle torque-controlled mounting process, especially for wide tires and run-flat tires

-

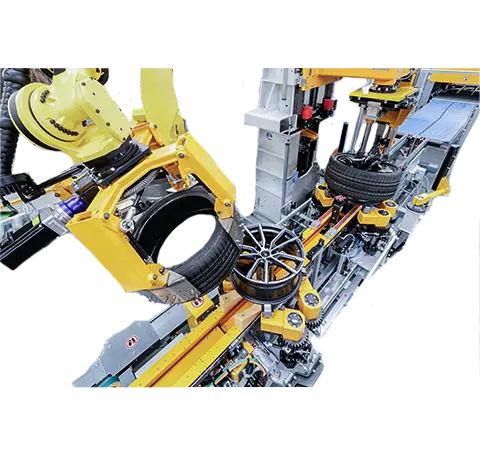

Wheel matching machines

-

The advantages of this principle are obvious: No additional machine is required thanks to gentle mounting and simultaneous matching without pressing the tire axially and without cycle time influence.

Wheel matching machines offer you a fully automatic solution for optimizing wheel assembly. Traditionally, the geometric values of the disc wheel (rim) are aligned with the tire uniformity parameters by means of targeted rotation, thereby optimizing wheel assembly. The matching process, or the targeted orientation of the two components in relation to each other, can be carried out either before or after tire mounting.Determination of the marking

- In order to perform a matching process, the tires and rims must have corresponding markings or the reference points must be known.

- Using an image processing system, the machine recognizes the tire manufacturer's marking for the radial force variation of the 1st harmonic on the tire sidewall and the rim manufacturer's marking for the geometric low point or high point on the rim.

- After image evaluation, the machine determines the required angle of rotation between the tire and rim to achieve optimal alignment.

- An alternative method is to measure the rim geometrically and relate the match point to the valve, defining this angle information as the angle of rotation once the valve has been detected by an image processing system.

Implementation of optimization:

- The tire, which is already mounted on the rim and not yet inflated, is pressed axially into the deep bed of the rim on both sides by segments preset to the inch size and held there.

- The rim can then be rotated to the previously determined angular position.

- The tire is then inflated with compressed air in the subsequent tire inflation bell.

- Alternatively, the tire can be oriented in the mounting machine using a process patented by Schenck.

- The markings are detected by a vision system inside the machine and superimposed by a robot, or the first tire bead is gently mounted by the robot.

- When mounting the upper, second bead, the points may twist slightly, but this has no adverse effect.

-

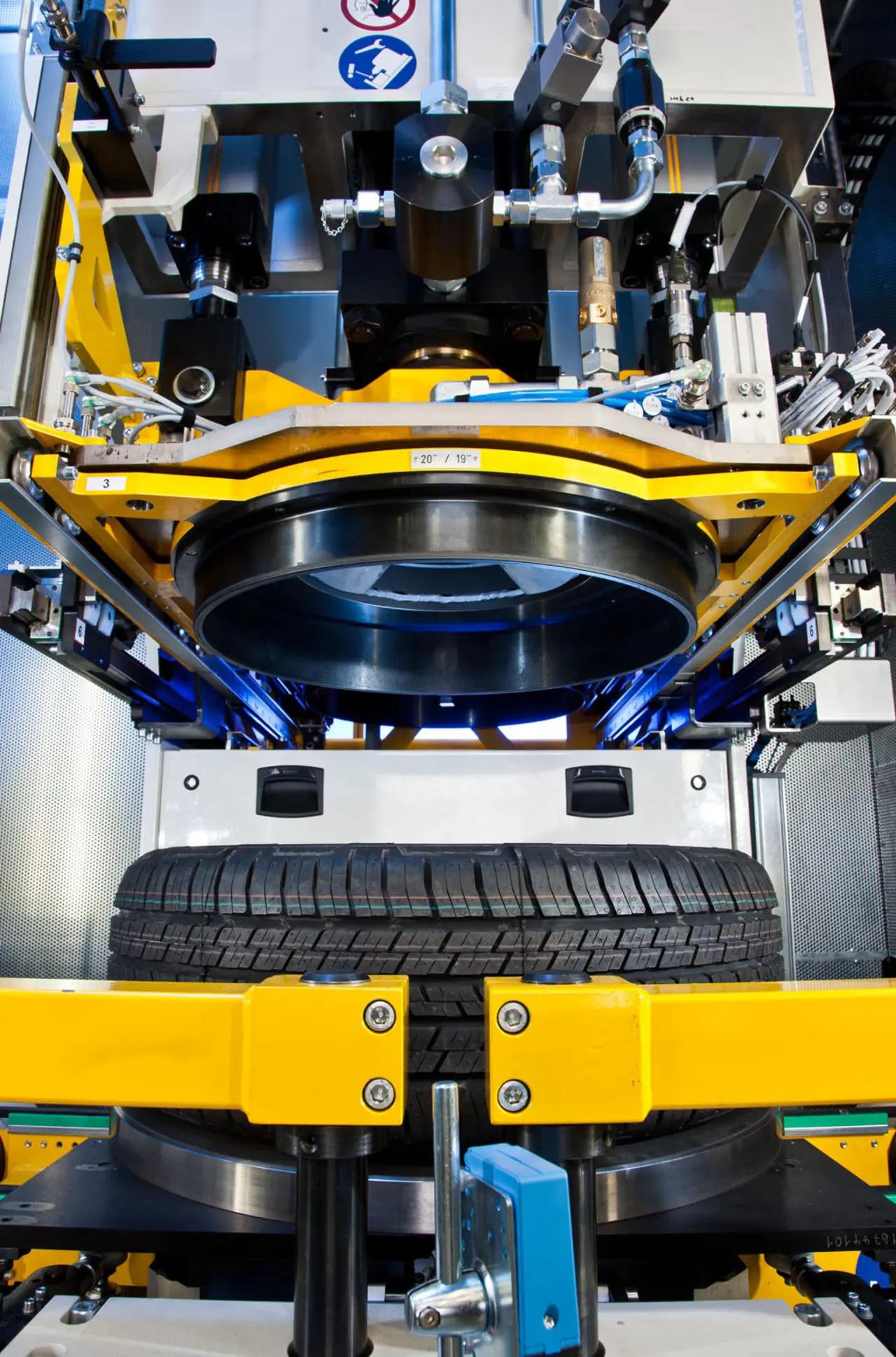

Tire inflation stations

-

Schenck tire inflation bells are specially designed for inflating passenger car, SUV, and commercial vehicle tires with compressed air. The compressed air is fed into the wheel assembly exclusively via a tire sealing ring and is, therefore, independent of the rim design. The different inflation bells offer varying degrees of flexibility depending on the number of inflation rings installed. In the maximum configuration, up to seven tire sealing rings in different sizes can be used for the appropriate selection depending on the rim geometry and tire sidewall.

Our machines offer:

- Highly flexible working range from 14" to 25"

- Individual filling ring configuration

- Cycle time-neutral filling ring changes in mixed operation thanks to patented filling ring magazine

- Highest filling accuracy

- Shortest cycle times

- Optimized filling and tire setting behavior thanks to our patented support table

- Reduction of compressed air consumption in the filling process through optimization of the filling bell design

- Constant filling pressure adjustment throughout the entire filling process

- Filling bell without rim sealing ring

- Extended working range (up to 7 filling rings)

- Can be used on any rim design, including alloy rims with rimless spoke design

- No axial stress on the A-side of the rims during filling operation

- Automatic function sequence and mixed operation

- Interlinking with production lines

-

Tire seat optimization

-

Our tire seat optimization complements your production and is designed to prevent possible changes in the tire seat under load during driving. Schenck offers various systems for this purpose, which optimize the tire seat by applying load. Depending on the wheel range, different solutions are available.

Whether a system based on conical rollers, a swiveling load wheel, or axial rollers on the tire sidewall is used, this must be determined based on your wheel program. We would be happy to advise you on selecting the optimal system tailored to your needs.

Our machines offer:

- Highly flexible working range from 14" to 25"

- Individual optimization programs can be adjusted depending on the type

- Selected solutions tailored to the respective wheel range

- Automatic function sequence and mixed operation

- Interlinking with production lines

-

Wheel uniformity measuring machines

-

Our wheel uniformity measuring machine (TU machine) checks the uniformity of complete car wheels precisely and reliably. It determines the force restrictions for radial and lateral forces and calculates other variables such as harmonics from these. As part of wheel production lines, they provide the parameters for evaluating complete wheel quality to ensure efficient quality control during the production process.

Our machines offer:

- Highly flexible working range from 14" to 25"

- Test drum diameter 854 mm

- Determination of radial and lateral force fluctuations, static lateral forces, cone and angle effects

- Calculation and analysis of harmonic forces (1st to 10th harmonic)

- Optional laser-based geometry measurement

- TUZ evaluation in conjunction with geometry measurement

- Optional DOT reading

- Shortest cycle times

- Automatic function sequence and mixed operation

- Interlinking with production lines

-

Wheel balancing machines

-

Our fully automatic wheel balancing machines enable cycle times of less than 10 seconds with a working range of 14" to 25". They measure the static and dynamic unbalance of complete car wheels and are suitable for both unbalance compensation calculation and unbalance control measurement.

Our machines offer:

- Fully automatic unbalance measuring machine in modular design that can be used for both unbalance compensation measurement and control measurement

- Innovative PC-based measuring system CAB 950W

- Extensive measurement and evaluation algorithms for the unbalance measurement and control balancing function

- Display and documentation of the measurement results in the balancing and horn planes as well as the static component of the unbalance

- Innovative unbalance measurement system allows “single-master” or empirical calibration

- Working range from 14" to 25"

- Shortest cycle time < 10 s

- Optional marking unit for unbalance marking in both compensation planes

- Ergonomic operating concept

- Integrated protective fence

- Quick and easy commissioning

- No special foundation is required! The Schenck measuring system can be installed on a standard industrial floor with a thickness of 200 mm without a special foundation.

- Schenck single-master calibration allows all wheel calibrations to be recovered with just one master wheel calibration. The specific wheel calibrations are traced back to the geometry data of the master wheel, so that the individual types do not have to be recalibrated

- Automatic reversal error check and calibration during production

- Automatic “self-control” process for checking the machine status during production

- Clamping technology features a low-maintenance sliding sleeve holder for individual clamping diameters, or optional universal, high-precision, and a backlash-free 10-jaw chuck for the clamping range 54 to 84 mm with face pull function for realistic clamping similar to that on the vehicle. (Other clamping ranges are available on request.)

-

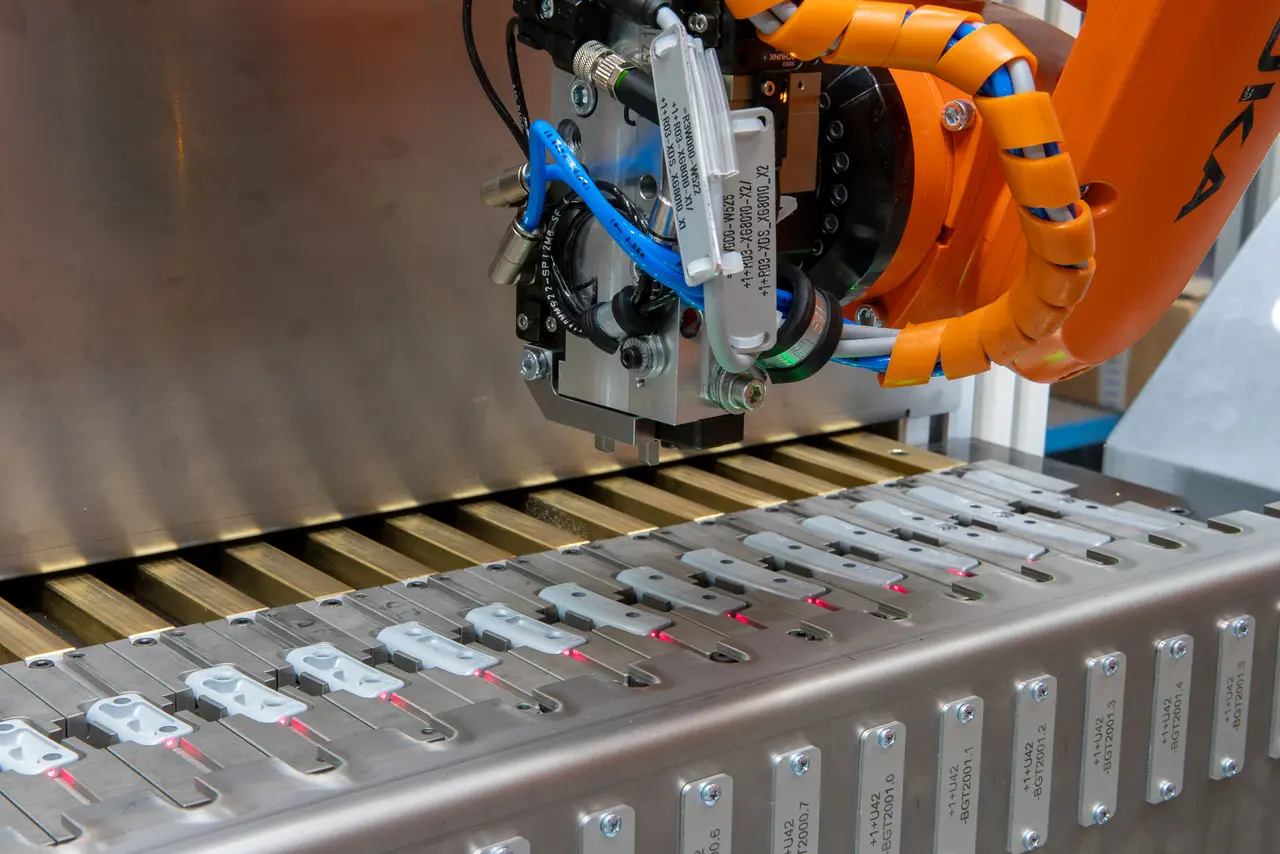

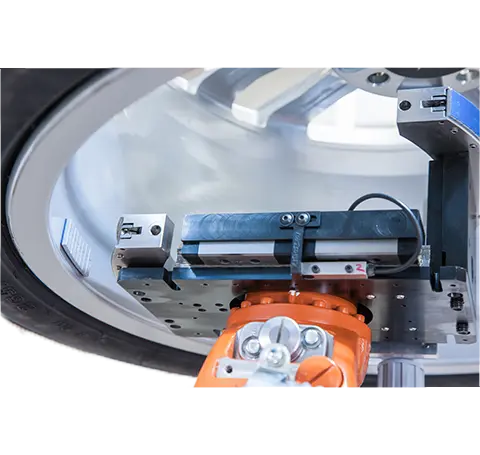

Unbalance compensation systems

-

Unbalance compensation systems include manual balancing stations for wheel assembly or rotor-based fully automatic balancing stations for all known types of balancing weights.

Manual balancing stations:

- The manual balancing station is an important component of a wheel balancing machine and is the standard solution in many wheel manufacturing facilities.

- The unbalance compensation values and their compensation positions, which are determined in the measuring system, are assigned to the wheel and transferred to the balancing station.

- The positions of the unbalance compensation are turned in facing the operator.

- The balancing weights to be used, including adhesive weights, 2-piece safety weights, or impact weights, are displayed on a screen and on the weight containers.

- A poka-yoke function supports the pick-to-light display and helps the operator quickly pick up the correct weights.

Fully automatic balancing stations:

- Our fully automatic balancing stations can be integrated directly into a wheel balancing system or operated as a stand-alone unit with its own control system.

- A highly flexible handling robot guides the wheels to the actual balancing device with precise positioning.

- Both 2-piece safety weights and various types of adhesive weights can be processed with defined and monitored contact pressure.

- The precise positioning and pressing process of the balancing weights ensures minimal residual unbalance and reliable bonding of the adhesive weights.

- The balancing systems achieve the shortest cycle times with very high system availability.

The advantages of this principle are obvious: No additional machine is required. Gentle mounting, simultaneous matching without pressing the tire axially and without cycle time influence.

-

Conveyor technology

-

A production line is the connection of individual systems to a complete production system. The supply of tires and rims, recognition of the components and a plausibility check can be taken into account, if necessary. If several lines are linked, there are entry and exit points and the finished wheels are to be kept in a storage system or delivered directly in sequence to the final assembly, the entire system quickly becomes complex. At the same time, the individual systems transfer the quality and production data to higher-level MES systems for complete traceability of the wheel parameters for quality assurance. With our many years of experience in the implementation and processing of greenfield systems, we are available to provide you with advice and support. We transport tires, rims and fully assembled wheels reliably, damage-free and efficiently.

Picture gallery Insight into Schenck complete systems for tire mounting