Sustainability & quality All about responsibility and safety at Schenck.

Schenck sets great store by an integrated management system. By a structure that combines the environment, quality and occupational safety all in one. This system is more than an organisational framework. It forms the basis for the excellent quality of our products and services – and for our continuous further development.

Sustainability at Schenck

Balancing and environmental protection – a logical connection

Sustainability is already firmly anchored in our corporate purpose. After all, balancing is a form of active environmental protection. A balanced rotor runs more smoothly, lasts longer and produces less noise. This consequently extends the service life of the machine – and helps protect resources. But we’re not satisfied just with balancing: we also work with clear standards and strategies to make our company and our products visibly and measurably more sustainable.

Our environmental management system

As early as the mid-nineties, Carl Schenck AG started implementing an environmental management system. With the decentralisation of the company, Schenck RoTec introduced its own environmental management system in mid-2001. In accordance with our environmental guidelines, we are committed to avoid substances that can be harmful to the environment or to human health. We use raw materials and energy sparingly, avoid producing waste and encourage recycling. To achieve our objectives, we invest in further training for our staff.

Dimension 1: sustainable management

We are convinced that sustainability and financial success go together, rather than being mutually exclusive. This is why we set great store by sustainable management: nearly all our sites operate 100% with green power. We have also developed a comprehensive climate strategy to reduce emissions in order to minimise our ecological footprint. We strive continuously to make our processes and workflows even more environmentally friendly.

Dimension 2: sustainable production

Balancing is lived sustainability. For us, this means constantly improving the precision and efficiency of our balancing solutions. Furthermore, we also pay active attention to sustainability and environmental production in the production of our balancing machines and measuring devices. Examples that document this include energy recovery at spin-testing rigs, minimum quantity lubrication, modern remote maintenance concepts and the use of efficient drive technology. Our customers benefit from sustainably and, at the same time, technologically leading balancing and diagnosis technology.

Our sustainability in numbers

-

Intelligent machine architecture reduces energy consumption by 50%

-

Lightweight construction and reducing the mass to be moved permit the use of smaller, more energy-efficient drives. Minimum quantity lubrication makes it possible to dispense with the complete coolant supply and treatment system. That reduces energy consumption and waste: downstream processing of workpieces follows on without interim cleaning, and swarf is recycled without further treatment. These measures have reduced energy consumption by 50% over two machine generations.

-

Vertical balancing machine boosts productivity by 13%

-

Our vertical balancing machine reduces cycle times by 8 seconds per minute. Over 19 shifts of 8 hours, this results in a saving of about 20 hours. For a year with 45 weeks of productivity, this means a saving of more than 900 hours. As a result, the machine’s energy balance is significantly improved, with a 13% increase in productivity.

-

Machines allow for up to 95% energy recovery

-

Drive amplifiers equipped for energy recovery make real sense in balancing machines with large masses. Feeding current back into the grid allows significant reductions in energy costs. AC servo-motors feed the energy generated by braking back into the grid, with significant cost savings. Reductions are normally around 85%, with even 95% possible under the most favourable conditions.

-

35% energy saved by substituting hydraulic drives

-

Wherever possible, our machines use pneumatic or electro-mechanical lifting, clamping and adjusting elements. They consume significantly less energy compared to hydraulic drives, with almost zero consumption in stand-by mode. The result: potential savings of around 35% compared to previous generations of machines.

-

Mineral casting reduces primary energy consumption by 30%

-

On the basis of our environmental guidelines, we undertake to dispense with materials that harm the environment or human health, in the processes involved in manufacturing our products. We make sparing use of raw materials and energy, avoid producing waste and advocate recycling. Mineral casting is one particular example here – this material is ideal for balancing machines, with its mechanical properties, outstanding damping characteristics and high thermal stability. The resource-saving production of mineral casting consumes up to 30% less primary energy compared to conventional materials such as grey cast iron, thus saving costs and reducing the burden on the environment.

The big picture at a glance As part of the DÜRR group, we assume ecological and social responsible along the supply chain.

Quality at Schenck

Excellent quality - the core of our brand

You can sense, feel, measure and experience the outstanding quality of our balancing solutions. We take measures to maintain this with firmly anchored quality management to safeguard quality, as well as our test laboratory, and also regular customer satisfaction surveys. In doing so, we help our customers to achieve the highest possible standards of production.

Quality management

Assuring quality – enhancing quality

The foundation for excellent quality is our certified quality management. This ensures compliance with our standards, and enhances both the quality and the service life of our products. Our quality management encompasses the following aspects:

- Quality/process management

- Health protection and operational safety

- Environmental management

- Risk management

Test laboratory for balancing technology

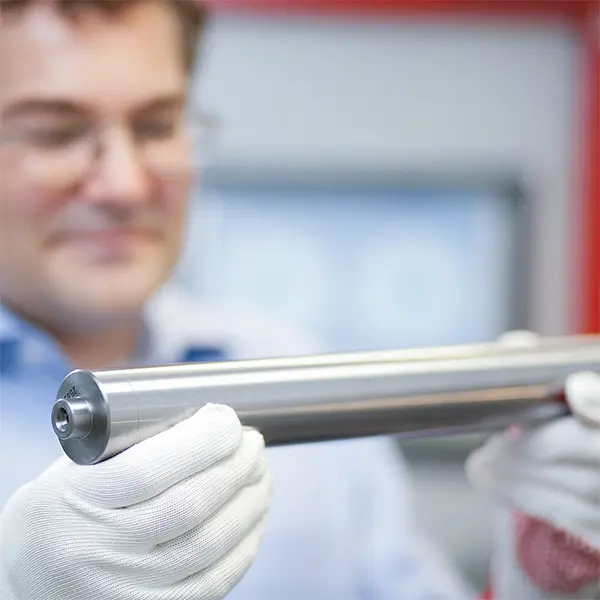

Globally unique expertise and precision

It is not only our integrated management system that is certified: our expertise in imbalance measurement is officially confirmed by the metrological authorities. Our accredited test laboratory for balancing technology is the only one of its kind worldwide, offering high-precision testing of working standards, such as test rotors or complete machines, with outstanding accuracy and repeatability.

Certificates

Since 2001, Schenck has fulfilled the very strict requirements set forth in the VDA 6.4 guidelines for the automotive industry. We have this checked by having external audits conducted every year. We have also successfully completed other certification processes: we have been certified to ISO 9001 already since the mid-nineties and this is perpetuated successfully year by year.

-

Germany

-

France

-

Datatechnic S.A.S.

Schenck S.A.S.

-

China

-

India